Machine Vision in the Electronics Industry

The electronics industry demands high precision, defect-free manufacturing, and strict quality control due to the complexity and miniaturization of components. Machine vision plays a critical role in ensuring the accuracy, consistency, and reliability of electronic assemblies, from semiconductor production to final device inspection.

Applications of Machine Vision in Electronics:

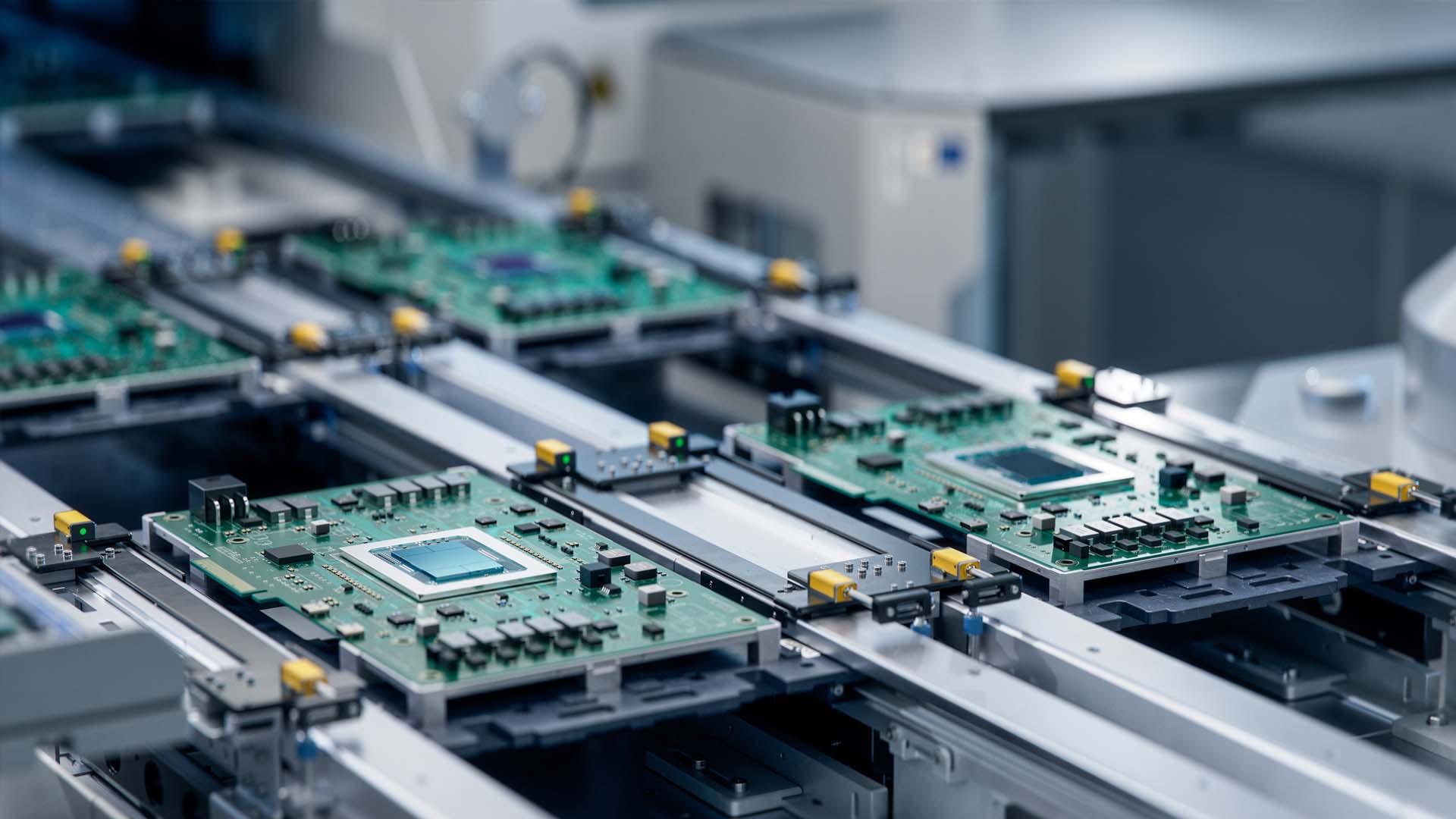

PCB Inspection: Machine vision systems detect soldering defects, missing components, misalignments, and micro-cracks on printed circuit boards (PCBs), ensuring compliance with design specifications.

Connector and Solder Joint Verification: High-resolution imaging verifies the correct placement, integrity, and quality of connectors and solder joints, preventing electrical failures in electronic devices.

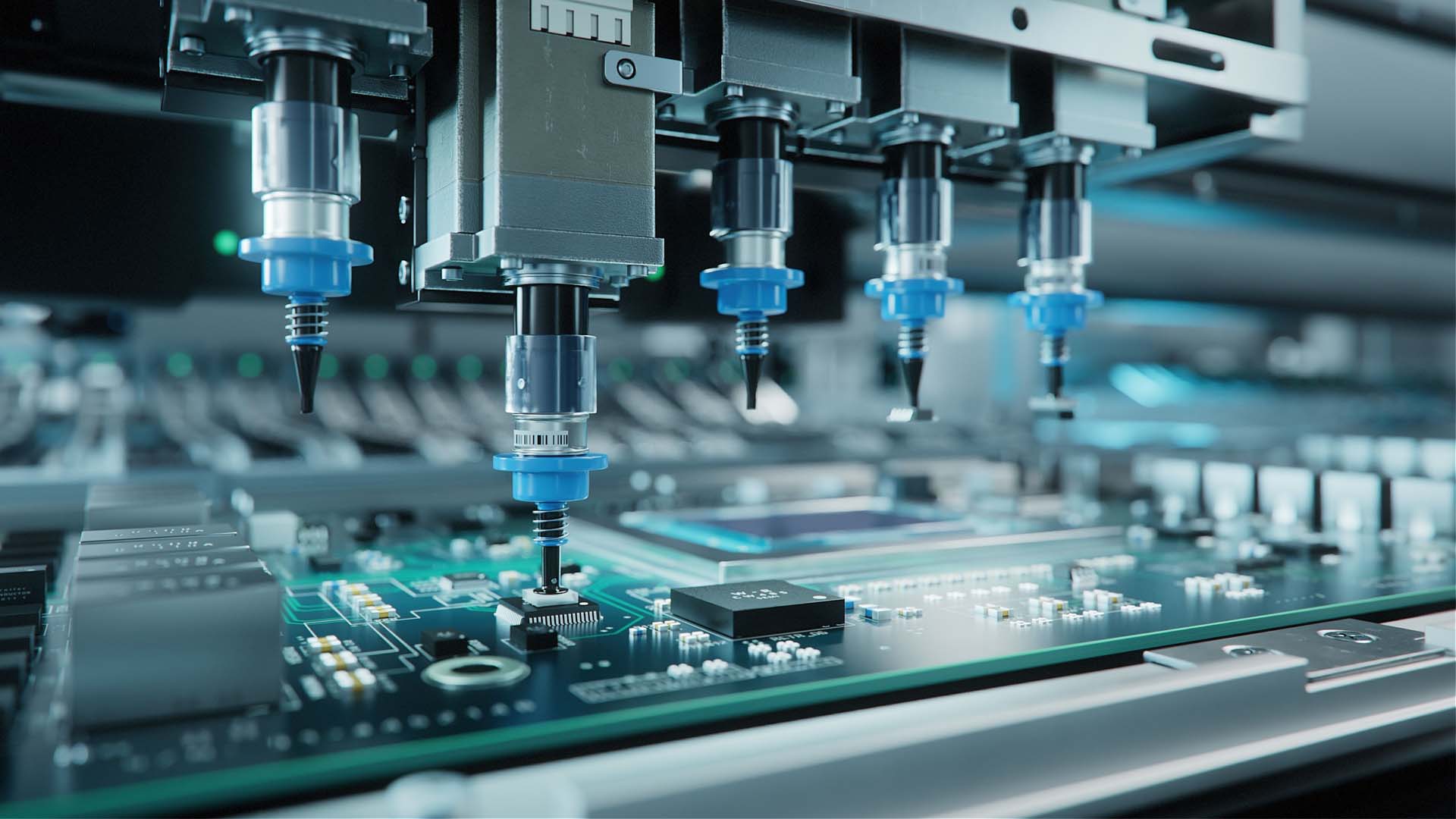

Component Positioning and Alignment: Machine vision ensures that small, intricate components are placed with extreme precision, a crucial factor in high-speed automated PCB assembly lines.

Surface Defect Detection: Optical inspection identifies surface defects such as scratches, discoloration, and inconsistencies in electronic enclosures and display panels.

Code Reading and Traceability: Vision systems scan barcodes, data matrix codes, and serial numbers on electronic components to enable full traceability throughout the production process.

Final Assembly Verification: Ensures that assembled electronic products, such as smartphones, laptops, and sensors, meet design and quality requirements before packaging and distribution.

PCB Inspection: Machine vision systems detect soldering defects, missing components, misalignments, and micro-cracks on printed circuit boards (PCBs), ensuring compliance with design specifications.

Connector and Solder Joint Verification: High-resolution imaging verifies the correct placement, integrity, and quality of connectors and solder joints, preventing electrical failures in electronic devices.

Component Positioning and Alignment: Machine vision ensures that small, intricate components are placed with extreme precision, a crucial factor in high-speed automated PCB assembly lines.

Surface Defect Detection: Optical inspection identifies surface defects such as scratches, discoloration, and inconsistencies in electronic enclosures and display panels.

Code Reading and Traceability: Vision systems scan barcodes, data matrix codes, and serial numbers on electronic components to enable full traceability throughout the production process.

Final Assembly Verification: Ensures that assembled electronic products, such as smartphones, laptops, and sensors, meet design and quality requirements before packaging and distribution.

Empowering electronics manufacturing

Achieve higher yields, reduce defects, and improve production efficiency while maintaining compliance with industry standards. Invest in Robovision’s advanced machine vision systems!