Color Control for Consistent Quality and Product Uniformity

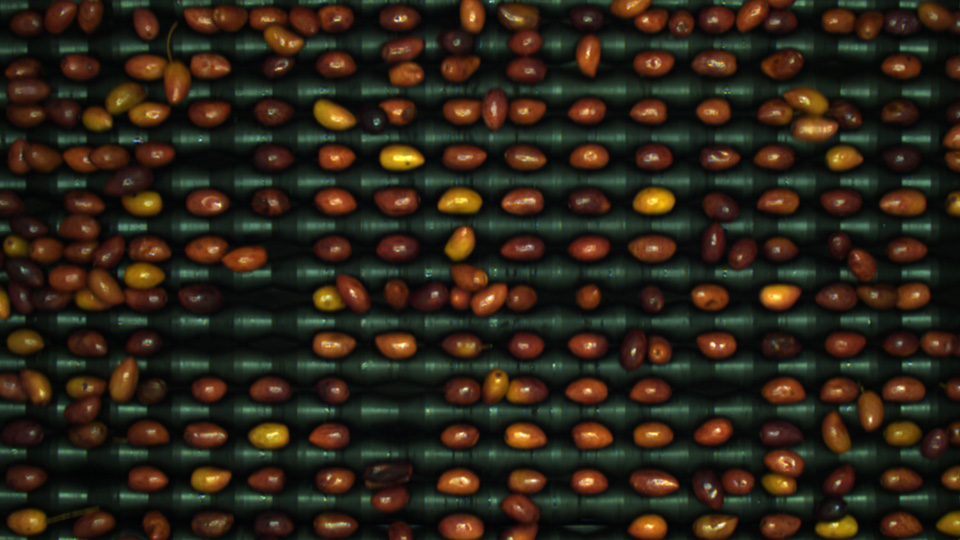

Even minor deviations in color can compromise a product’s appearance, create issues with brand identity, and lead to costly returns. Factors such as lighting, material texture, and viewing angle affect perception, making color analysis a highly demanding process.

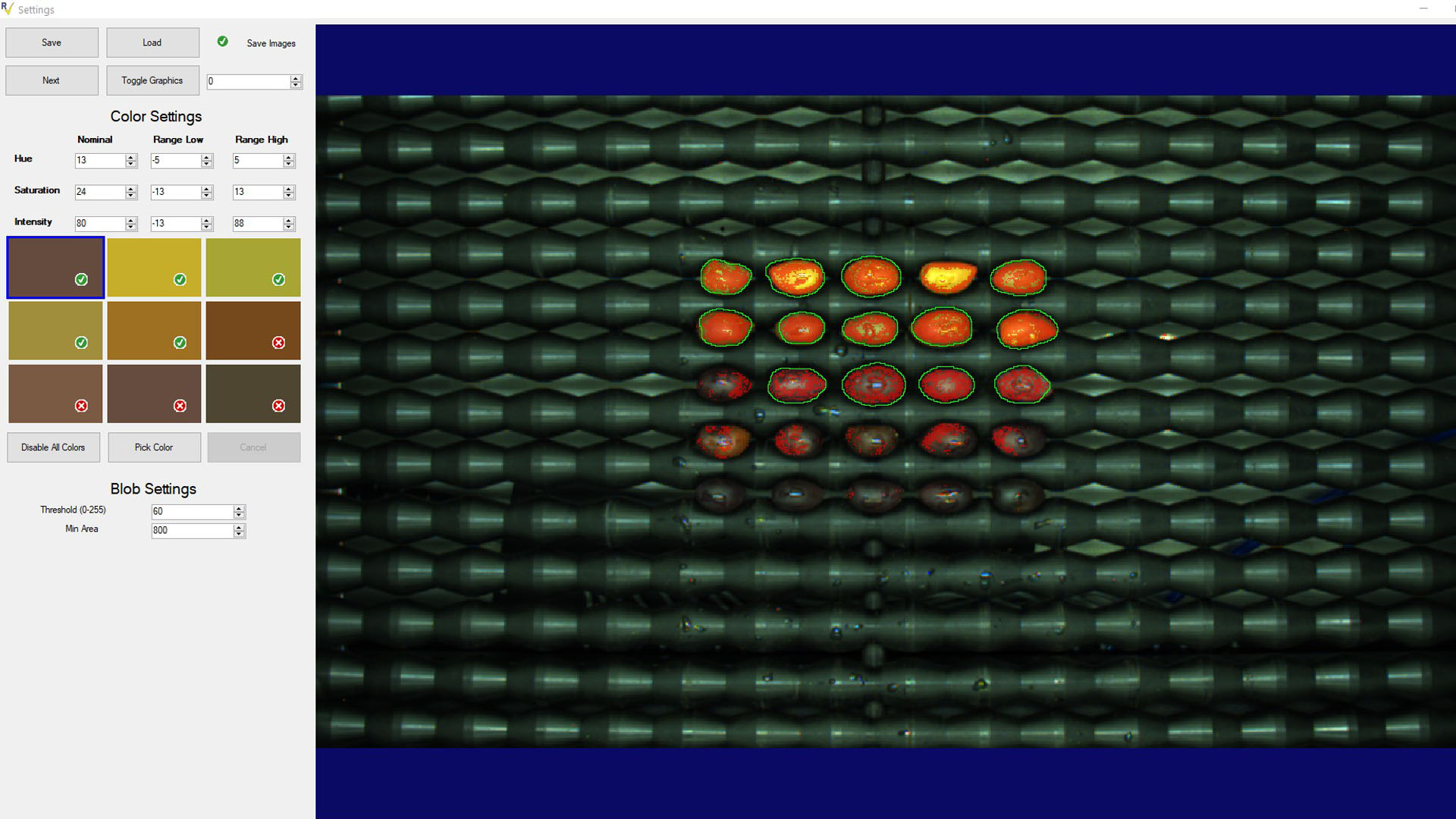

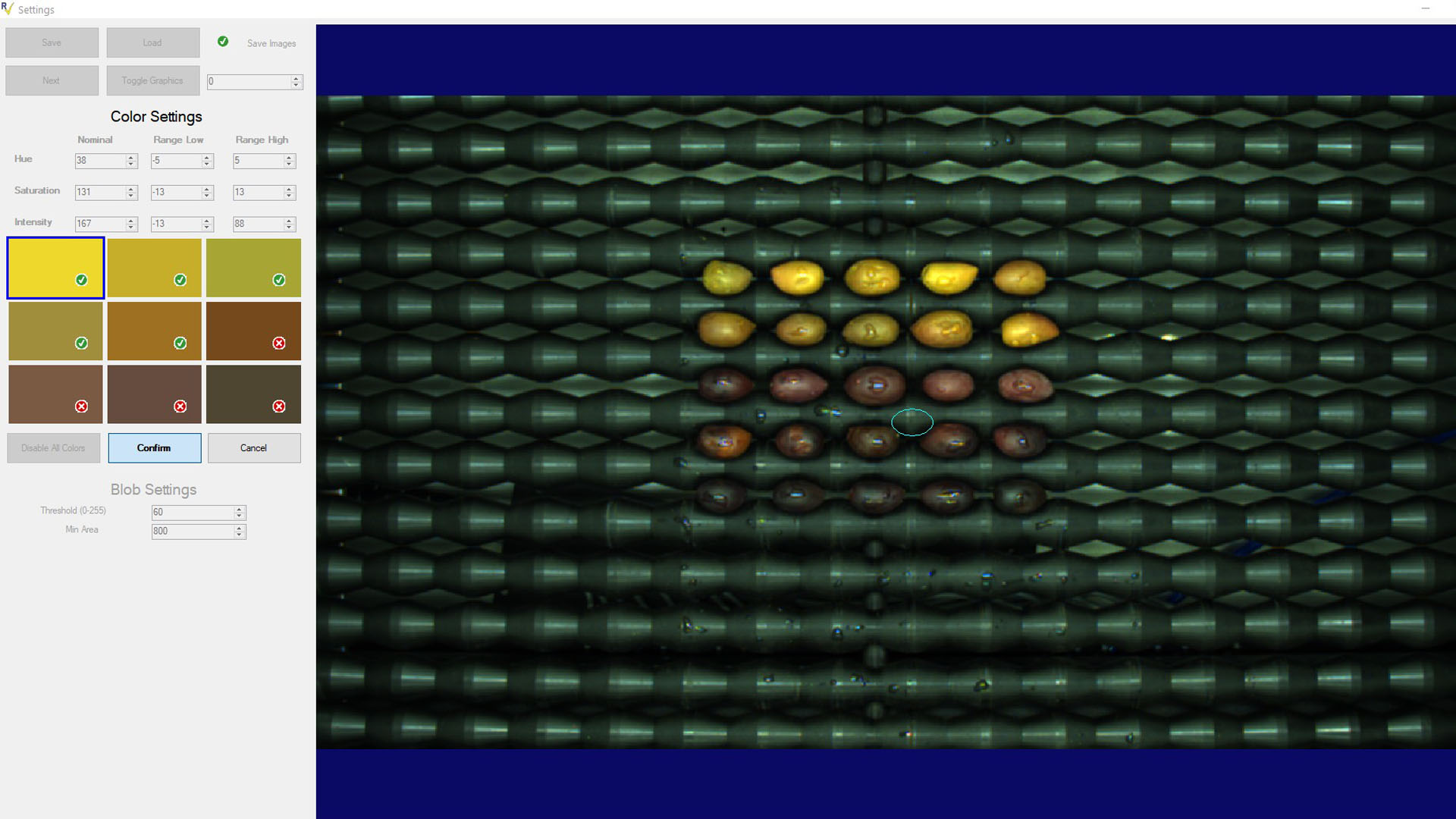

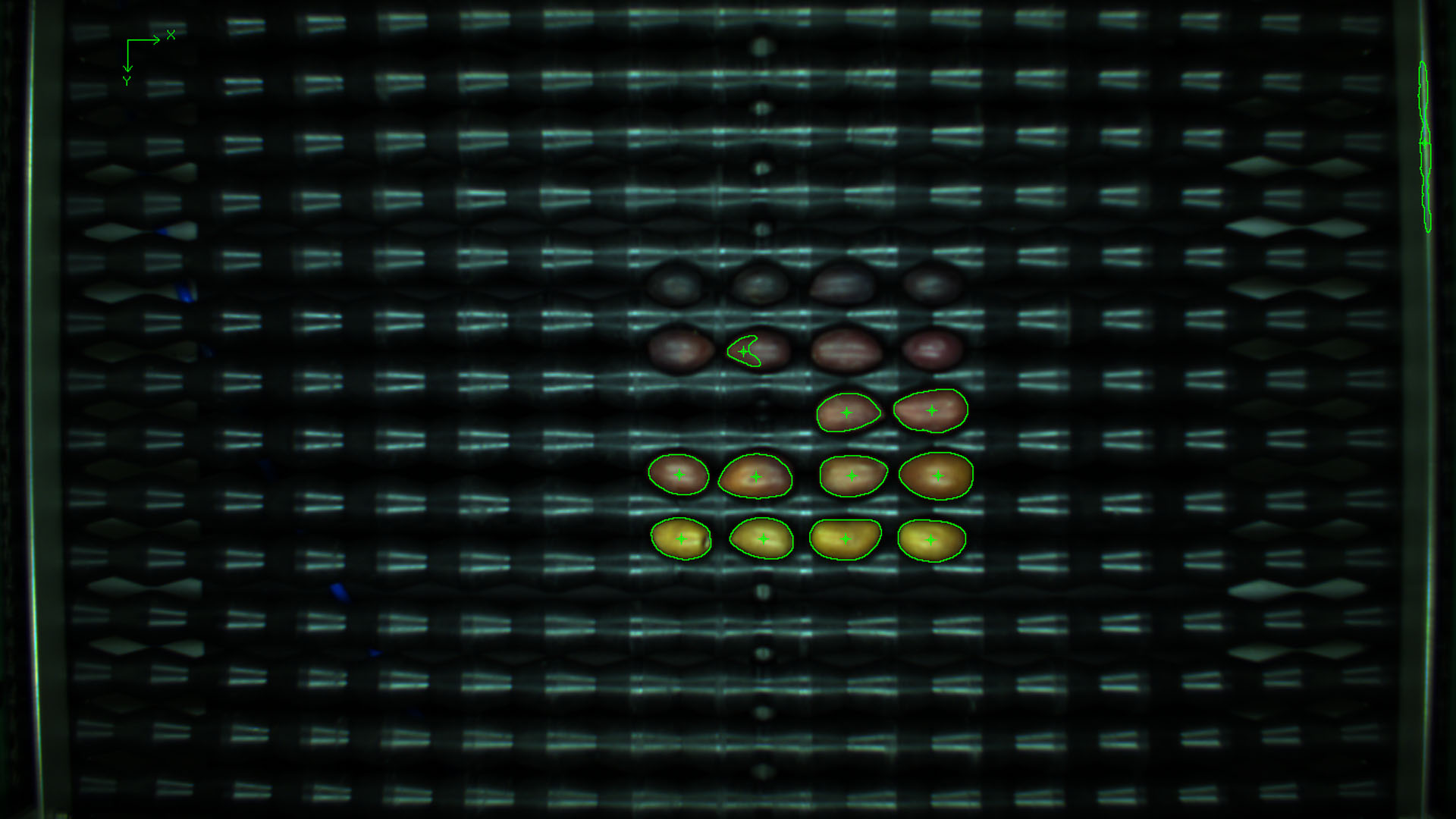

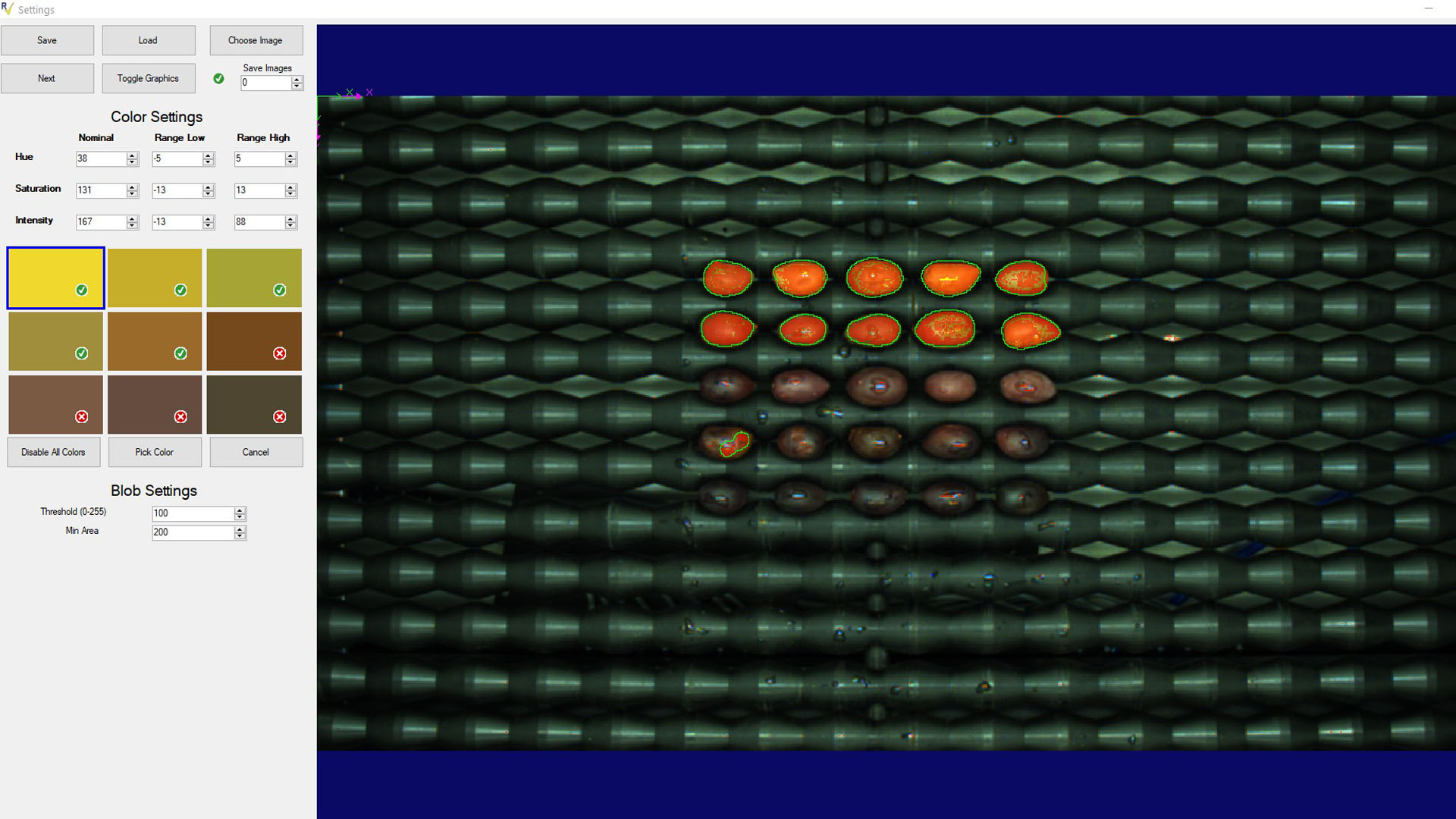

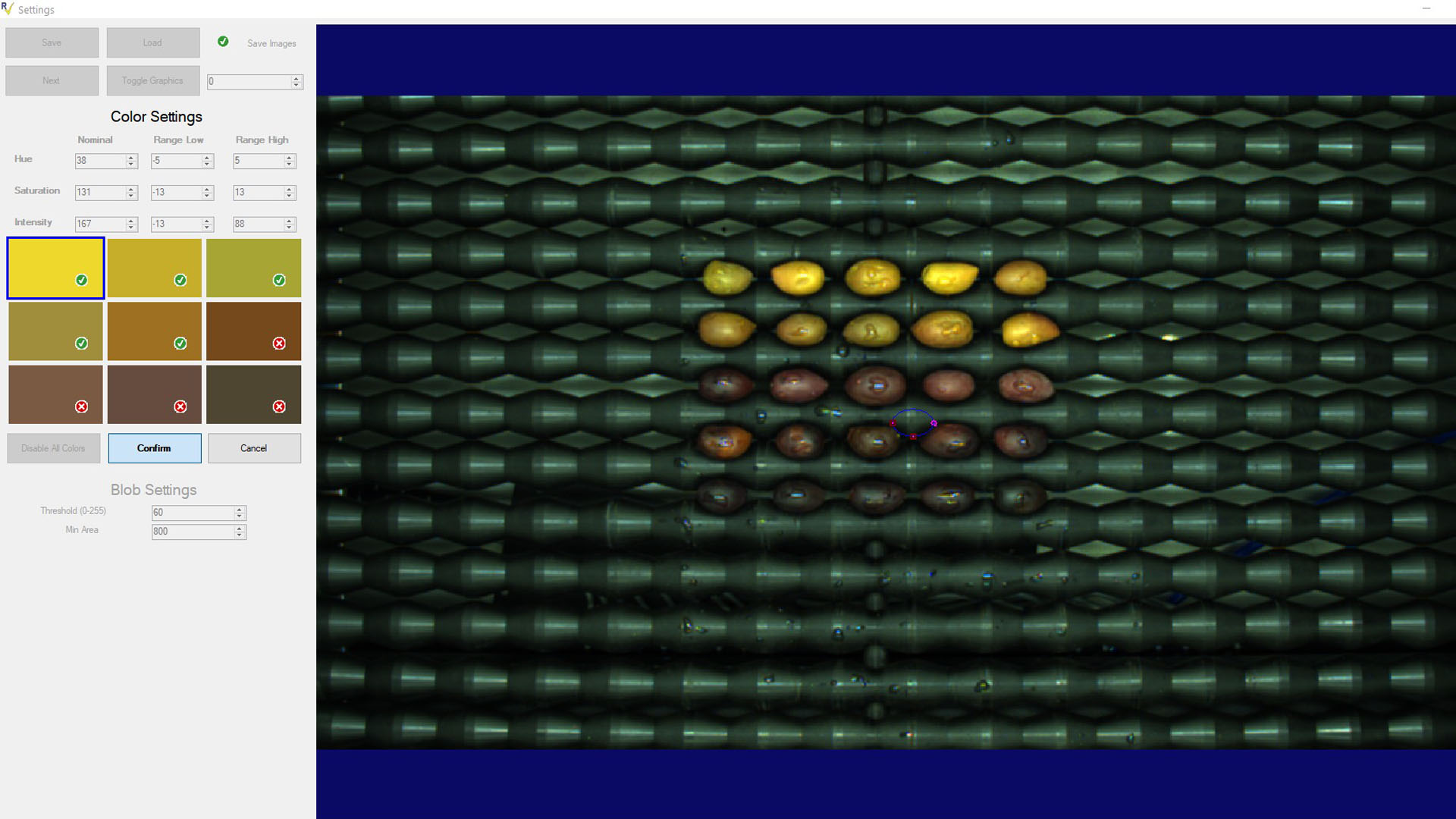

With calibrated lighting and advanced algorithms, color inspection systems ensure reliable and consistent measurement, detecting deviations in shades, tones, and patterns even in challenging production environments.

Key Features & Benefits

Color Deviation Detection: Identifies inconsistencies in shades, tones, and patterns to ensure color accuracy.

Print Accuracy Verification: Confirms that logos, labels, and packaging are printed with correct colors and proper alignment.

Reference-Based Comparison: Measures colors against predefined standards, ensuring compliance with design specifications.

Consistency Monitoring: Detects subtle color variations during production, reducing scrap and rework.

Applications Across Industries

Our color inspection technology is invaluable in industries where color accuracy directly impacts product quality, including:

Food & Beverage: Ensures accurate colors on packaging, labels, and products for brand consistency and regulatory compliance.

Cosmetics: Verifies uniformity in packaging and product appearance (liquids, powders).

Pharmaceuticals: Monitors label accuracy, packaging color codes, and compliance with strict quality standards.

Textiles: Guarantees uniform color across fabrics and patterns.

Printing & Packaging: Validates print colors and alignment to maintain brand integrity.

Deliver products that stand out for their quality and consistency, building lasting trust with your customers.