3D Vision for Precision Measurements and Advanced Quality Control

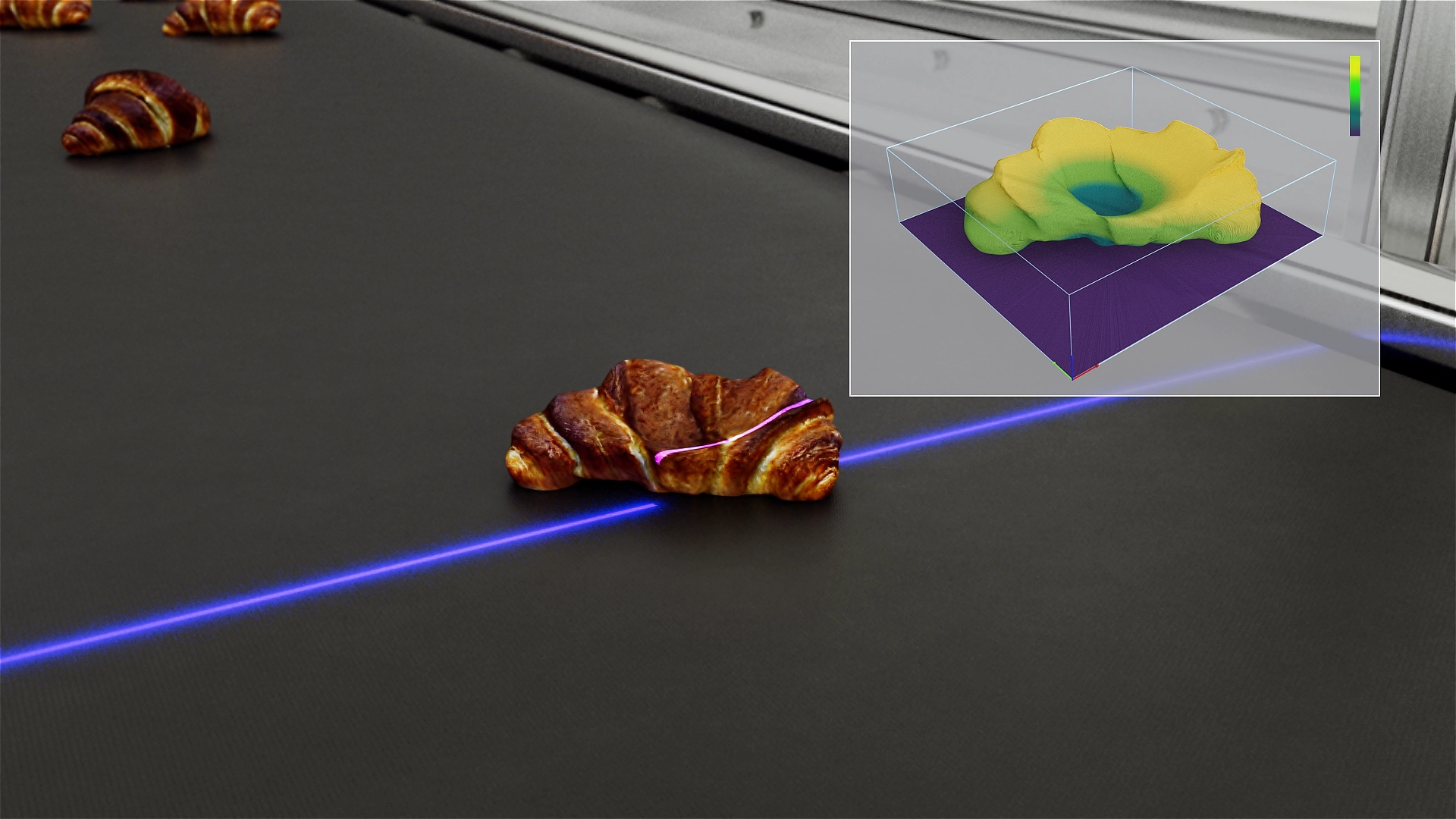

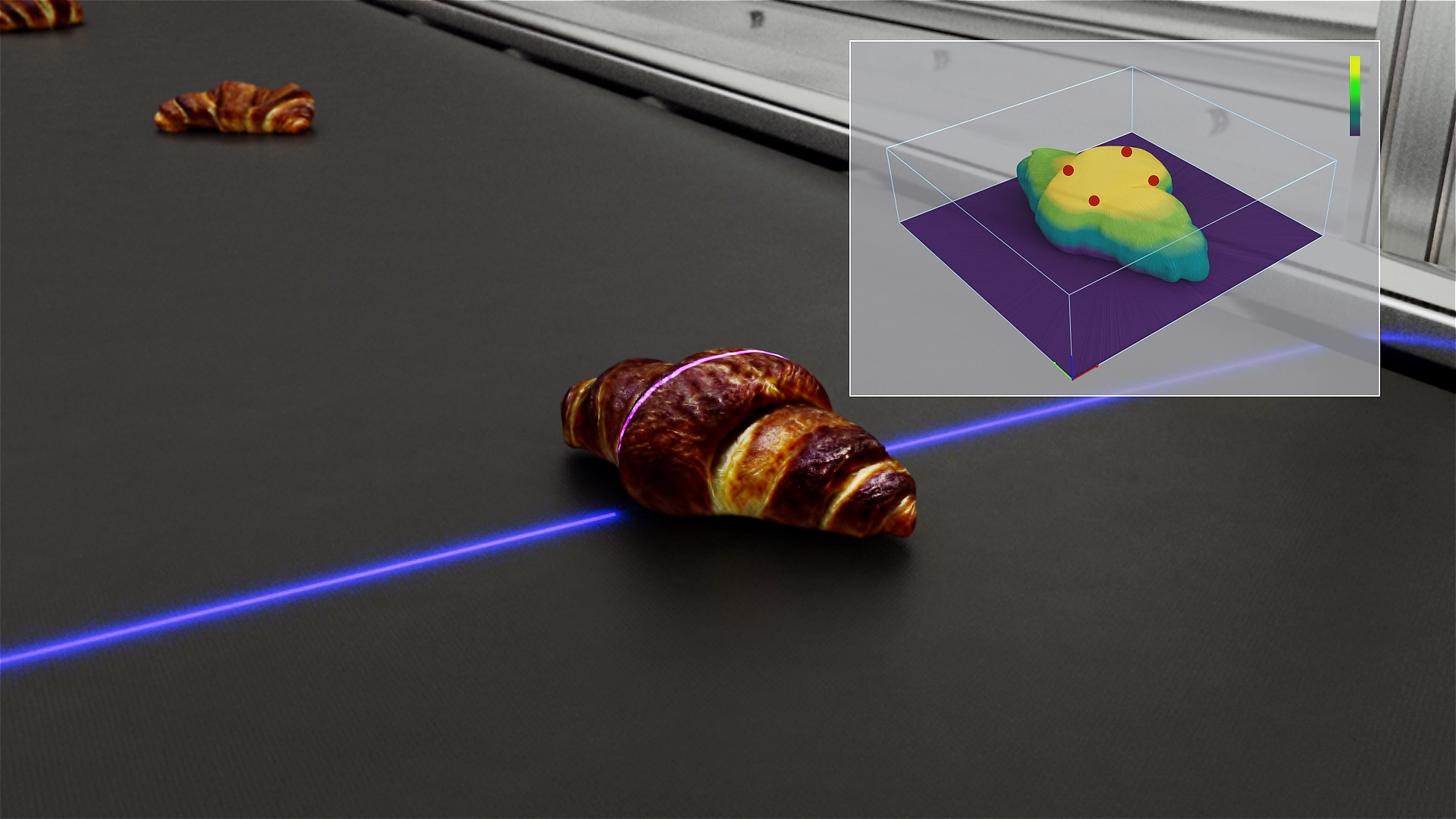

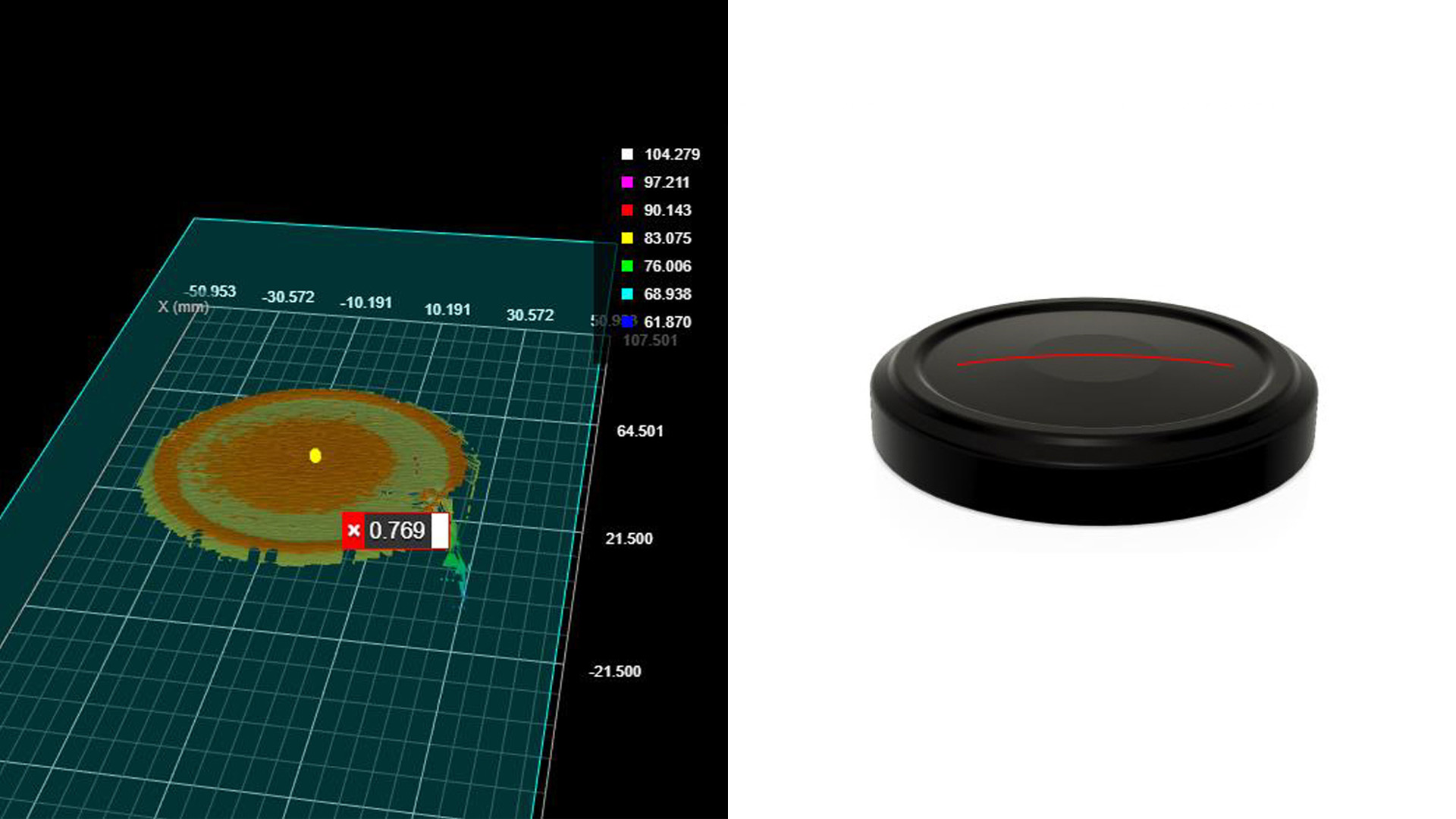

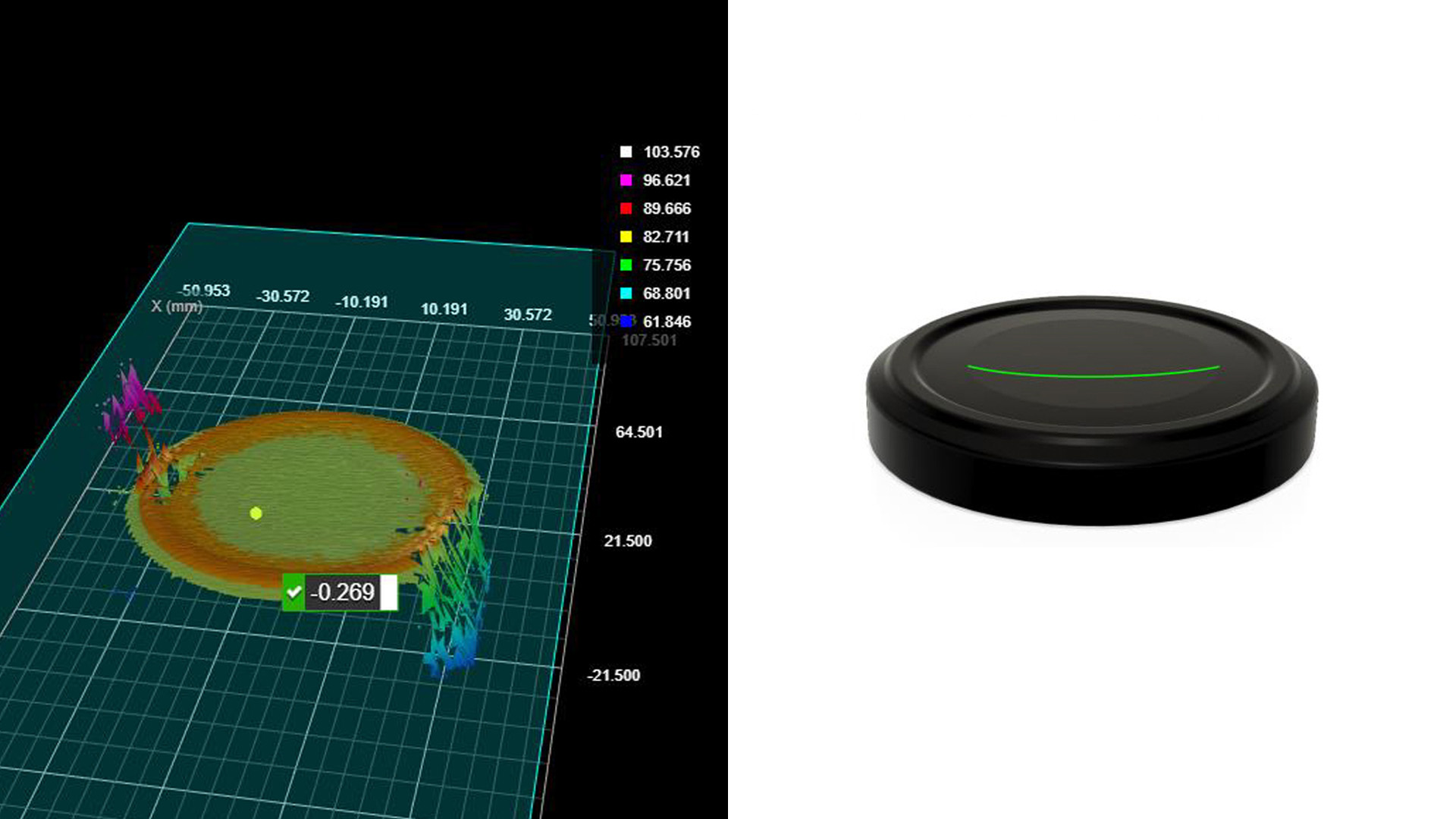

Even the slightest dimensional deviation or an almost invisible defect can lead to costly rework, delivery delays, and loss of customer trust. 3D vision systems capture depth and spatial data with exceptional accuracy, ensuring reliable measurements and thorough quality inspection at every stage of the process.

Key Features & Benefits

Accurate Object Analysis and Measurement: Inspects geometric characteristics (height, volume, X, Y, Z dimensions) with absolute precision.

Reliable in Challenging Environments: Stable operation even under low contrast or variable lighting conditions.

Robotics Enhancement: Provides guidance to robots for bin picking, assembly, sorting, and material handling, boosting efficiency and reducing the need for manual intervention.

Flexible Integration: Can be implemented in both new and existing production lines, with seamless connectivity to automation systems.

Advanced Imaging Techniques: Analyzes complex geometries, reflective, and semi-transparent surfaces with consistency and precision.

Reduce scrap, cut operational costs, and ensure consistent quality control for every product.