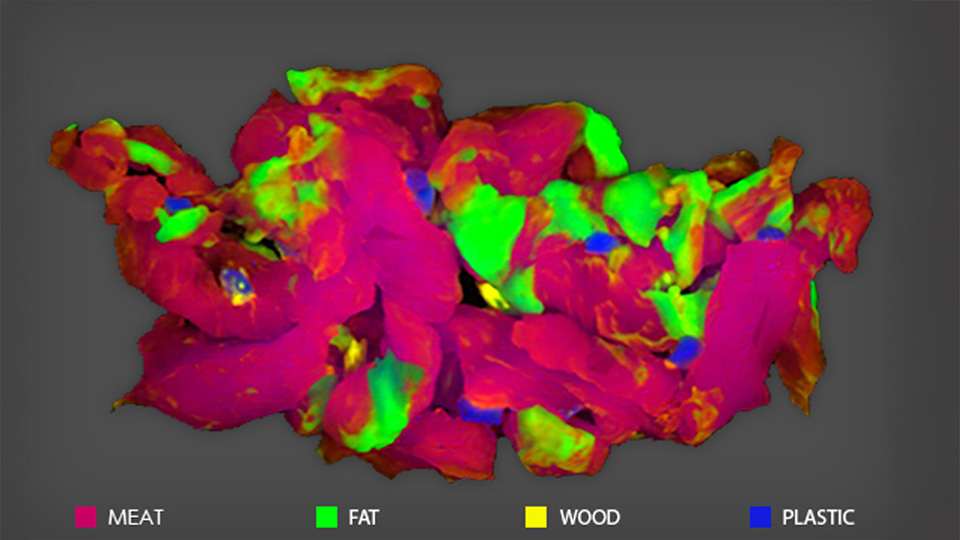

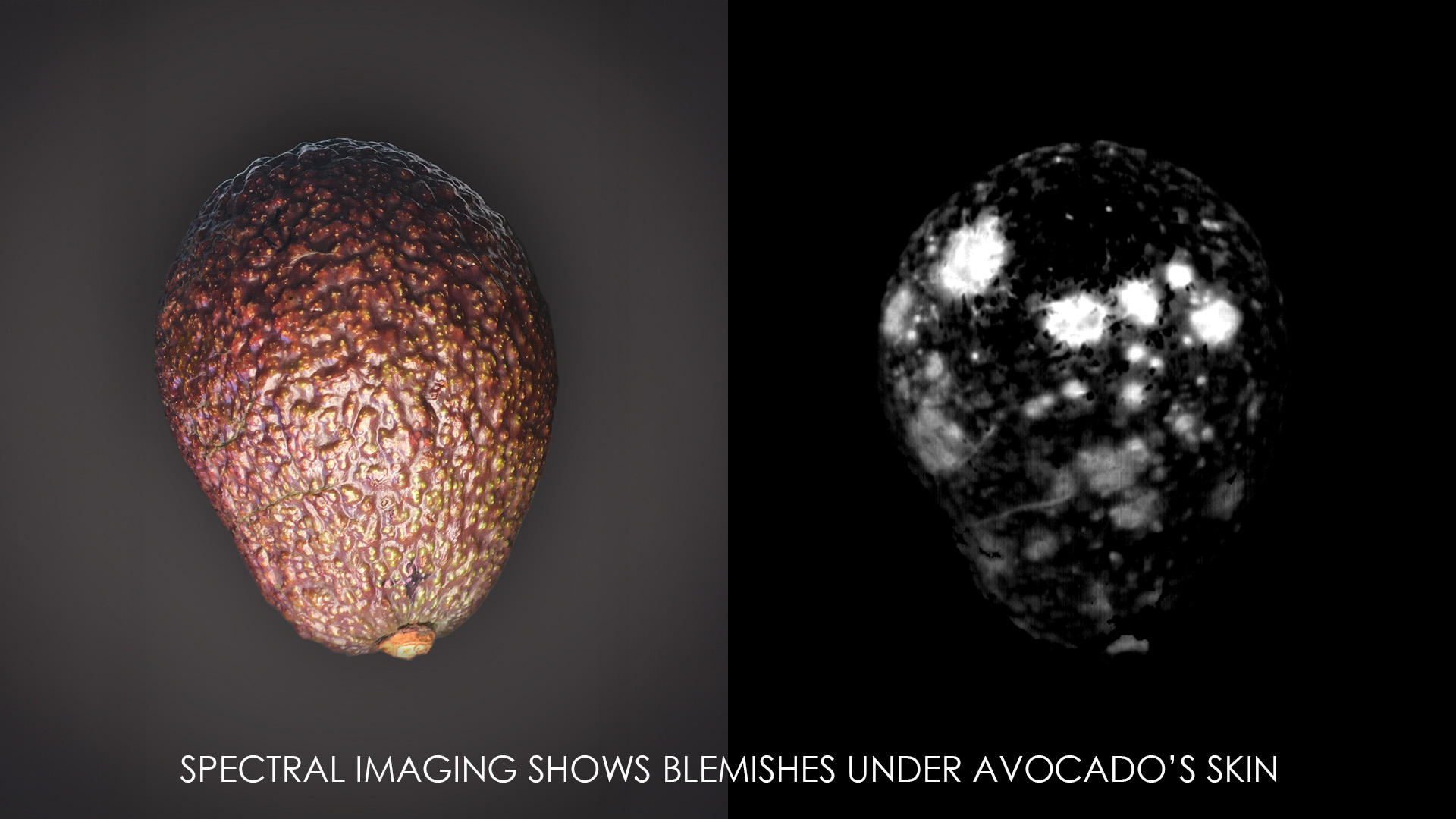

Spectral Imaging for Material Differentiation and Quality Control

In industrial production, detecting foreign objects or analyzing product composition often relies on conventional methods that fail to identify contaminants or accurately separate different materials. This results in higher scrap rates, product returns, and increased quality control costs. Spectral imaging overcomes these limitations by capturing data across multiple wavelengths of light, revealing properties that standard systems cannot detect.

It operates in two key forms:

Multispectral Imaging: Captures fewer than 20 wavelength bands for targeted analysis.

Hyperspectral Imaging: Captures over 20 wavelength bands for a comprehensive understanding of material properties.

Key Features & Benefits

Material Identification: Analyzes and classifies materials based on their spectral signatures and chemical composition.

Wide Spectral Range: Covers from visible light to infrared, enabling applications across diverse industries.

Real-Time Data: Provides immediate insights for dynamic production environments.

Enhanced Detection: Identifies subtle defects, contaminants, and impurities that conventional systems may overlook.

Applications Across Industries

Spectral imaging strengthens quality control and production efficiency across a wide range of sectors, supporting both qualitative and quantitative analysis:

Food & Beverage: Detects contaminants, verifies product composition, and classifies ingredients with precision.

Agriculture: Monitors crop health, assesses moisture levels, and detects early signs of disease.

Recycling: Differentiates plastics, metals, and other materials for accurate sorting.

Pharmaceuticals: Ensures compliance with specifications and detects foreign bodies.

Textiles: Evaluates dye uniformity and identifies surface defects.

Leverage spectral imaging to detect invisible contaminants, analyze material properties with accuracy, and maximize production efficiency.