Know-How in Practice

Know-how becomes meaningful when it’s tested in real-world conditions. Our portfolio includes tailored solutions already implemented in leading companies across multiple industries, from food and pharmaceuticals to cosmetics, plastics, and metal processing

Each implementation reflects our consistent commitment to providing intelligent, bespoke machine vision systems that enhance operational efficiency, minimize error rates, and ensure a fast return on investment.

Each case study reflects the same core philosophy: user-friendly yet technologically advanced solutions, designed to adapt seamlessly to the specific demands of any production line. Whether it’s enhancing legacy equipment or integrating into new facilities, our goal is to maximize performance and ensure rapid payback, with tangible results in quality, speed, and reliability.

Machine vision for blister inspection: eliminating defects and scrap.

We upgraded a pharmaceutical production line with a fully integrated visual inspection system, eliminating errors, minimizing waste, and ensuring every blister pack meets the highest standards of quality and compliance. Read the whole story!

Error-free production: real-time inspection of bottles and dispensing pumps.

We delivered a visual inspection system that guarantees flawless orientation and pump integrity for one of the world’s leading cosmetic brands. The AI-powered solution that we developed enhances production quality, seamlessly operating in a fast-paced environment. Read the whole story!

Machine vision and AI for reliable inspection of plastic containers

Gain insight into how we empowered a leading company in the plastics industry to meet the highest standards in its production, reducing operating costs and increasing accuracy, through the development and installation of an automated inspection system.

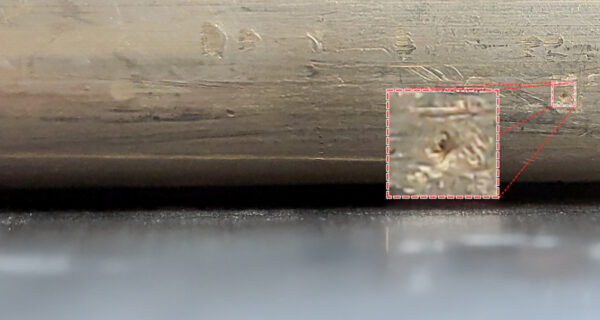

Innovative 3D laser-based inspection system for aluminum conduits.

We engineered a tailor-made 3D inspection solution capable of detecting even the slightest flaws in aluminum pipes. This solution enhanced the production line to meet global quality standards without missing a beat. Find out more!

Machine vision system for high-precision quality in tortilla production.

With a collaboration spanning over two decades, one of the world’s most respected food industry giants tasked us with a high-precision quality control system for tortillas -a product moving at 70 meters per minute. Once again, we proved our capability to deliver excellence under the pressure of fast-paced production challenges. Discover more!