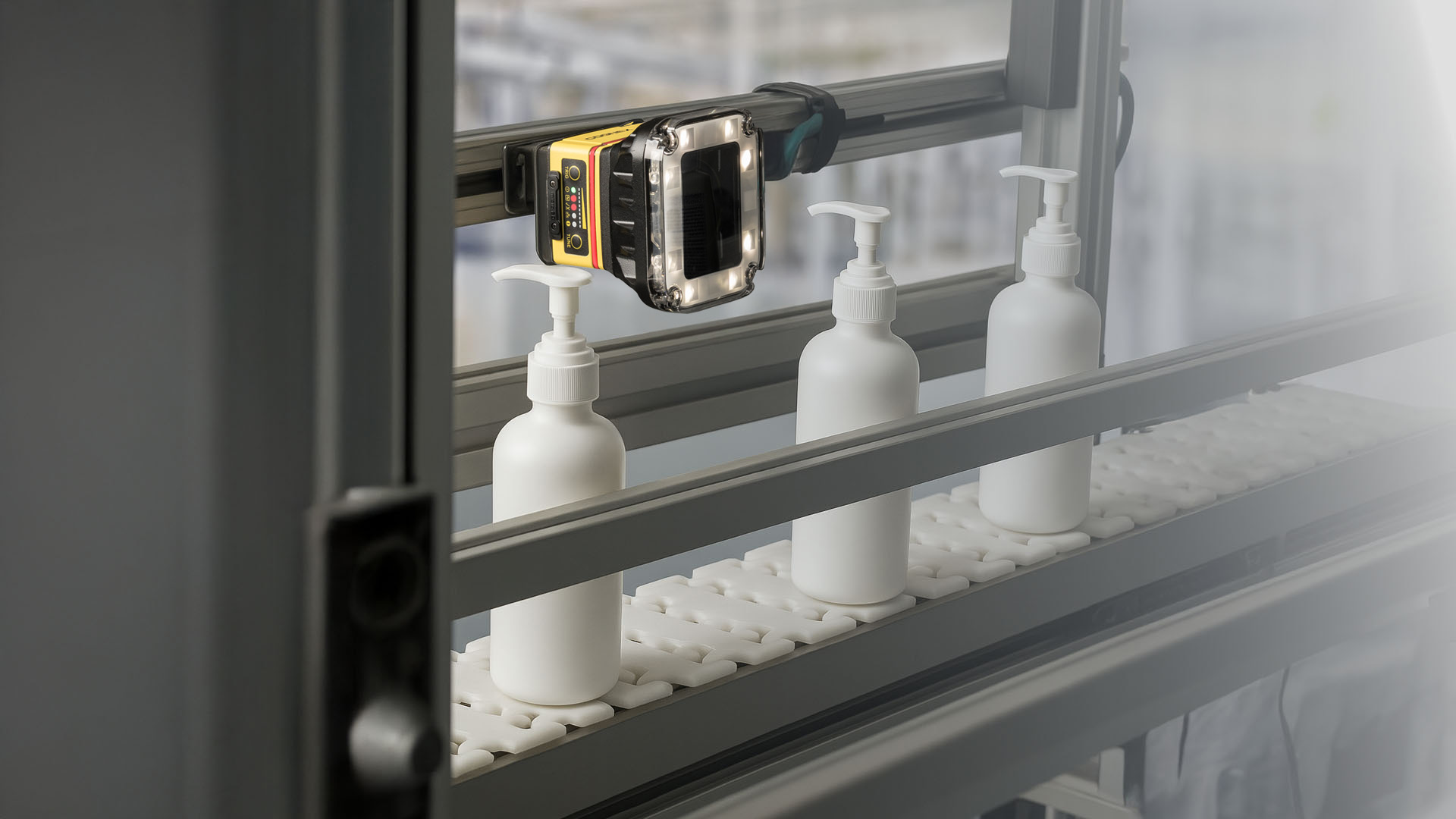

Cosmetics Visual Inspection: Bottle Orientation and Pump Control

For a global giant in the personal care industry, top quality is a non-negotiable standard. This application was developed as part of our long-standing collaboration with a sector leader who was facing a challenge on their bottle production line.

Technical Challenge and Solution

It may seem simple, however, the direction in which the bottles arrived from the feeder to the production line created a chain of problems: incorrect cap placement, incorrect label alignment, and incomplete presentation of the final product. When it comes to a large brand, such failures are unacceptable.

In this context, the goal was clear: to ensure maximum accuracy in controlling the orientation of each bottle, regardless of type or shape.

We have developed an advanced yet easy-to-use machine vision system that:

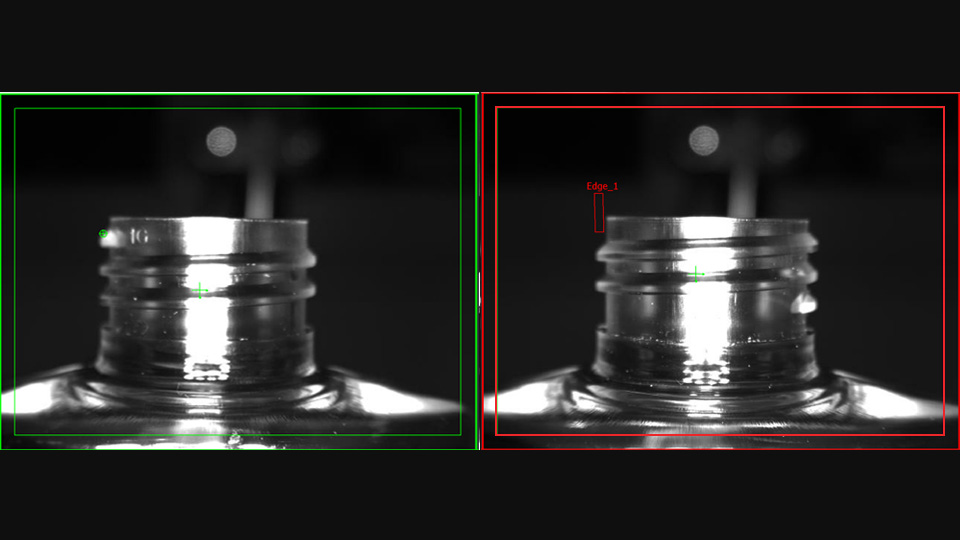

- Recognizes the correct orientation of the bottle based on a geometric reference point (such as a cross on the bottle body)

- Detects the edge through edge detection to confirm correct positioning

- Responds accurately even on shiny or reflective surfaces

- Automatically rotates any bottle that is not in the correct position, without interrupting the flow

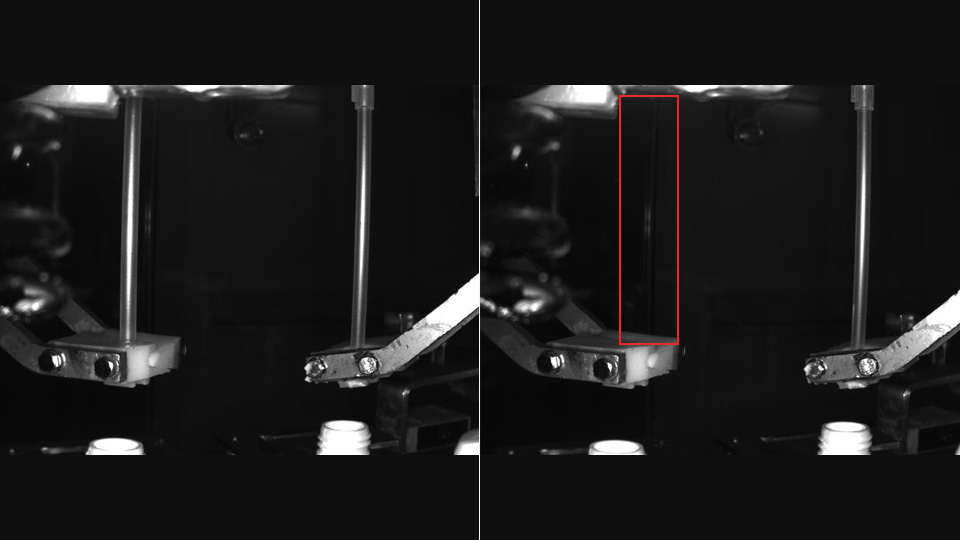

In the next stage, the presence and integrity of the pump tube inside the bottle are checked:

- Through predefined areas of interest, the system recognizes whether the tube is present, missing, or broken

- The processing is based on pixel shade analysis to ensure accuracy

- The control is performed separately in the left and right positions for each pump

- The system comes with a user-friendly parameterization interface, allowing the line operator to create or modify control programs without specialization.

The results were immediate and substantial:

- 100% correct bottle orientation

- Minimization of errors in caps and labels

- Full control for each pump

- Simplicity and flexibility in use

Application Αdvantages

The system’s installation was accompanied by clear benefits, highlighting the effectiveness and efficiency of the solution. Specifically:

- Compatibility with different bottle designs and materials

- Possibility of real-time rejection of defective pieces

- Trainable and customizable platform, adapted to the needs of the operator

The trust this group has placed in us for over 15 years is no coincidence — it is the result of continuous growth and an unwavering commitment to quality. The system we implemented is more than just a solution; it has become a benchmark for the entire industry, in an environment where even the smallest detail defines a brand's prestige.

Enhance your brand image with machine vision solutions that guarantee accuracy and consistency in every product.