Machine Vision Quality Control System in Tortilla Production

Our client is a leading American multinational with over 150 years of history in the food industry. Its continuous commitment to quality has established it as a global leader in its category. Our collaboration with this company spans more than two decades, during which we’ve provided automation solutions across every stage of production. The trust we’ve built over time was reaffirmed when they once again chose us for a critical project: quality control of tortillas.

Despite strong competition from international suppliers, our selection for this project reinforces the prestige of our long-standing partnership and confirms the company’s continued confidence in our expertise, capabilities, and reliable support.

Technical Challenge and Solution

In this specific project, the requirement was the precise and continuous quality control of 8 and 10 inch tortillas – at speeds of around 70 meters per minute, during their transport from the cooling chamber to the clean room, where the Counter Stacker Thermoformer is also installed.

The control system was placed at a critical point in the line, before the stacking process, with the aim of maximum possible reliability in control and the timely detection of any deviating tortilla. This need is particularly high, as the Counter Stacker and the automatic loading system (Robot Loading System) require the tortillas to be perfectly separated, flat and of the correct diameter, in order to form stable stacks.

The inspection is performed in two product distribution patterns:

- 8-inch tortillas in 5 rows of 24 pieces per press (5x5 pattern with a gap in the center)

- 10-inch tortillas in 4 rows of 16 pieces per press (4x4 pattern)

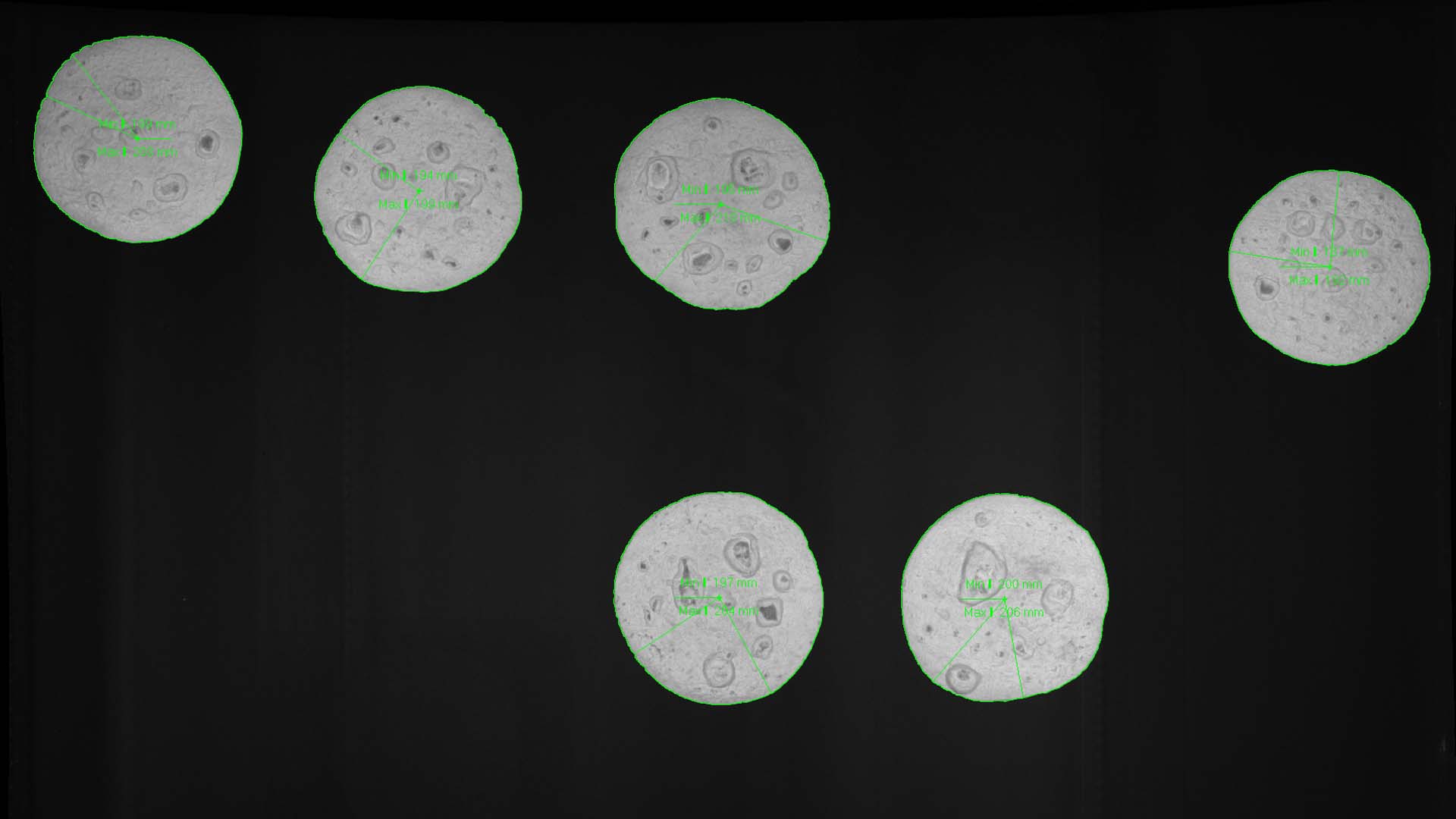

The inspection system checks each tortilla for the following characteristics:

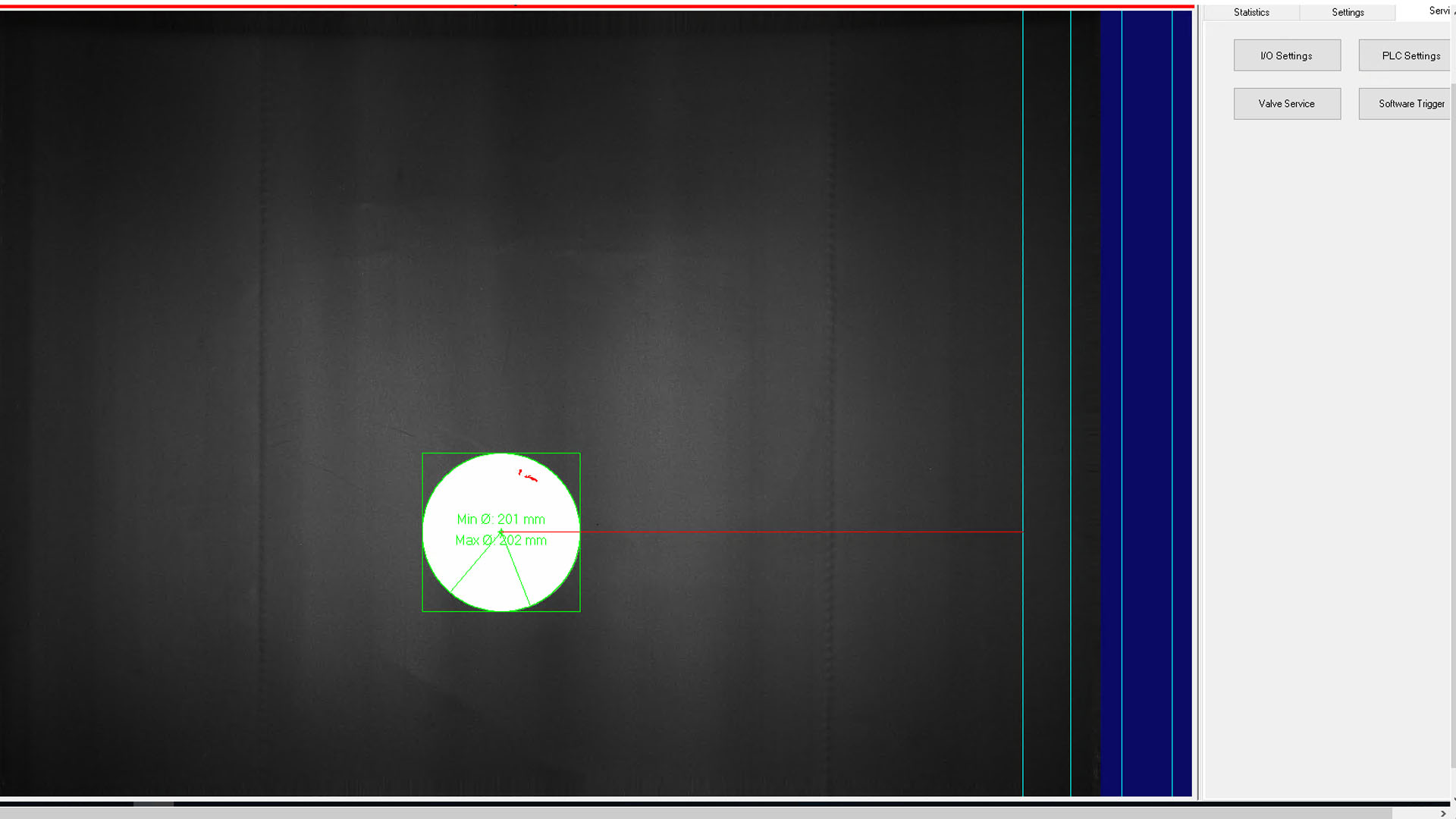

- Maximum and minimum diameter

- Folds (folded tortillas)

- Overlaps between pieces

- Holes and surface imperfections

- Irregularities in the contour

- Deviation of the center from the ideal stacking line

The implemented solution includes:

- 2D machine vision system, with a 16MPixel GigE camera and a special encoder that synchronizes the inspection with the line speed

- 15” touch screen (Aaeon) for real-time visualization and system parameterization

- Conveyor INOX sanitary tape, with blue Habasit cleanline belt

- Airborne rejection system with high-pressure air nozzles and 24VDC FESTO valves

- Separate rejection belt, positioned vertically in the main flow, for the safe removal and recycling of defective tortillas

- Central PLC system with Rockwell Automation (CompactLogix), HMI PanelView, PowerFlex inverter, and full connectivity via industrial protocol EtherNet/IP

The installation was carried out inside the clean room, with a controlled temperature of 18–25°C, ensuring conditions of absolute cleanliness and accuracy.

The control system was implemented at the production line's most critical point, just before the stacking and packaging phase. At this stage, any deviation in the tortillas' shape, position, or condition can lead to malfunctions in the subsequent automated processes.

The prevention of such deviations through automated and detailed control ensures:

- Smooth and uninterrupted operation.

- Uniformity in the final product that reaches the consumer.

- Reduction of subsequent rejections, thus saving resources and time.

The implemented solution does not simply replace human control – it makes possible a process that human resources could not perform at the speeds and with the required accuracy. The machine’s construction and system specifications were designed according to the customer's requirements, ensuring absolute compatibility with existing production processes and its strict quality standards.

Application Αdvantages

The installation and deployment of the system delivered immediate benefits, validating both its effectiveness and the return on investment:

- Increased efficiency throughout the production line, through flawless feeding of the Counter Stacker

- Optimization of product quality, with a drastic reduction in deviations in the shape, diameter, and condition of the pies

- Real-time monitoring and system adjustment capabilities, tailored to production line requirements and product specifications

- Compliance with strict clean room hygiene standards, thanks to the open frame design, INOX materials and easy cleaning

The solution was seamlessly integrated into the existing production environment without disrupting operational flow. It also enhanced reliability, improved flexibility, and enabled future upgrade potential.

Ensure consistent product quality with machine vision solutions that meet the most demanding production speeds.