3D Inspection of Aluminum Pipes with Laser Profiler Technology

In the metallurgical industry, precision is a non-negotiable requirement, especially when it comes to aluminum pipes used in high-demand energy and industrial applications. In such cases, quality control down to the last millimeter is absolutely critical.

After evaluating a solution from an international inspection systems provider and finding it insufficient for their needs, the client chose to entrust us with the design and development of an advanced, fully customized 3D inspection system. Capable of detecting even the slightest surface defects, the solution was seamlessly integrated into the production line, delivering exceptional accuracy and reliability without disrupting operations.

Technical Challenge and Solution

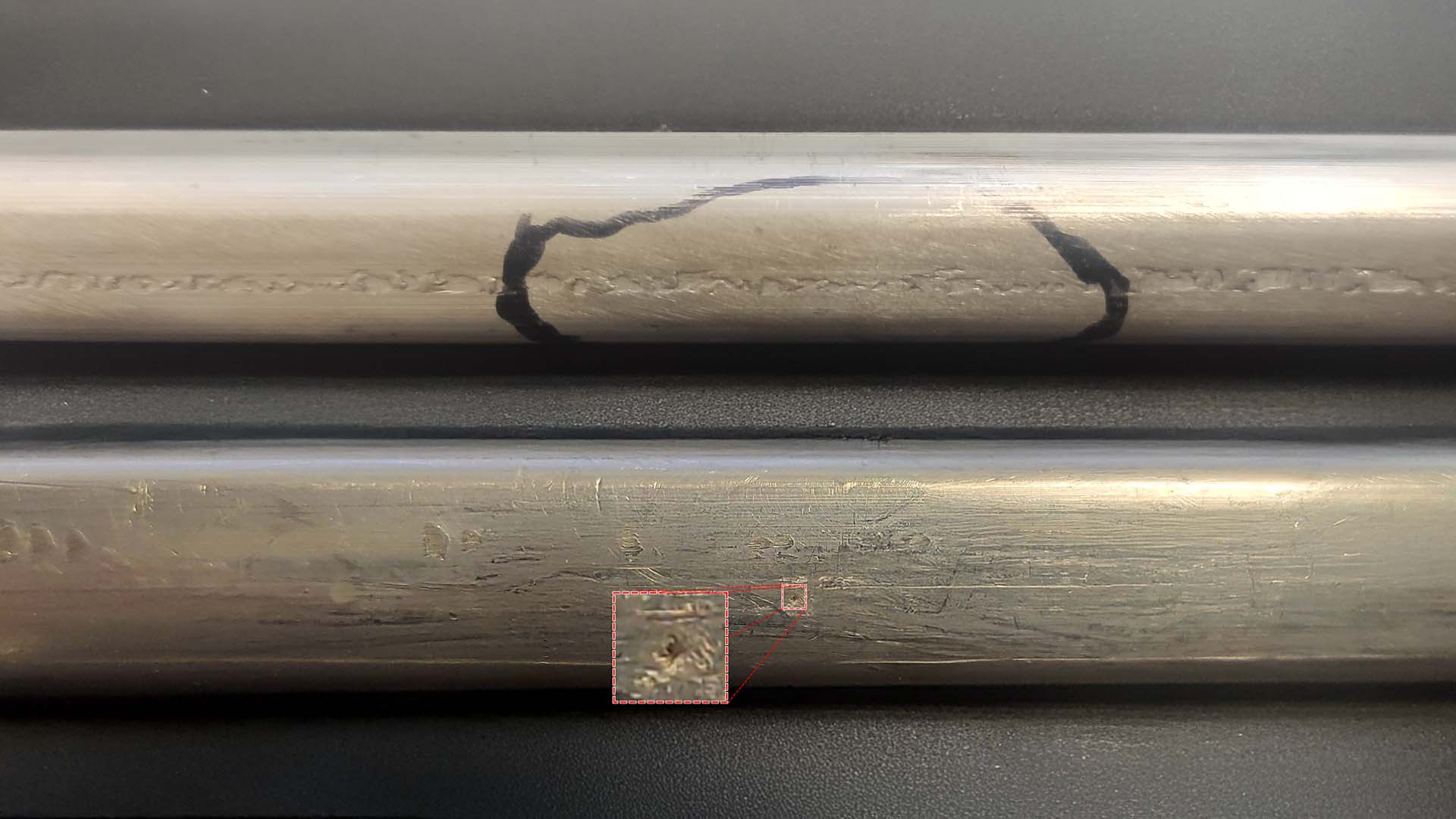

The challenge was complex: surface quality control with micrometer accuracy, at high speed and tight tolerances. During rolling, the pipes present potential imperfections such as:

- Dents and bulges

- Scratches and pinholes

- Surface irregularities with deviations of the order of 0.1mm

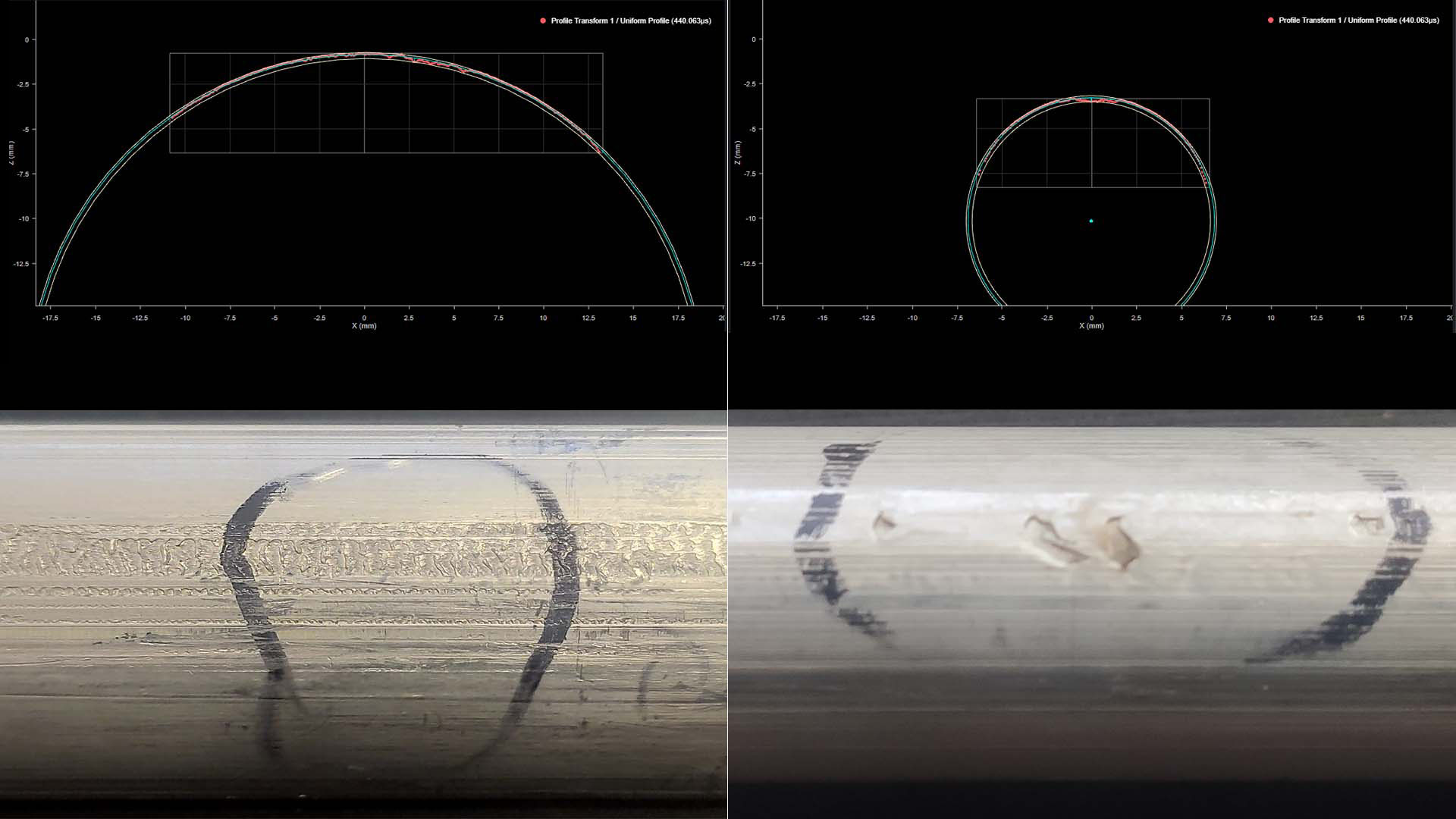

The solution was designed around four high-precision 3D laser sensors, placed around the perimeter of the pipe inside a protective canopy.

These sensors:

- Scan up to 10,000 profiles per second

- Operate with a blue laser for optimal response to metal surfaces

- Achieve a resolution of 60μm in the feed axis and 40μm in the width axis

- Communicate with each other with full calibration to cover the entire perimeter without blind spots

The system has a built-in web interface and supports remote access via IIoT. It automatically generates detailed production reports per batch, including:

- Type and location of error

- Size of deviations

- Date, time and LOT number

In the event of an error, an audio-visual alarm is activated, or the deviation is highlighted for subsequent intervention, without interrupting the production.

Application Αdvantages

The results were immediate and impressive:

- Accurate and repeatable detection of shallow defects

- Reduction of human inspection and related errors

- Enhancement of traceability and documentation quality

- Improvement of the reliability of the final product

Our innovative solution gave the unit a competitive advantage, upgrading quality to an internationally recognized level and creating new standards in metal surface defect inspection.

Gain uncompromising control with 3D systems that guarantee quality in every millimeter.