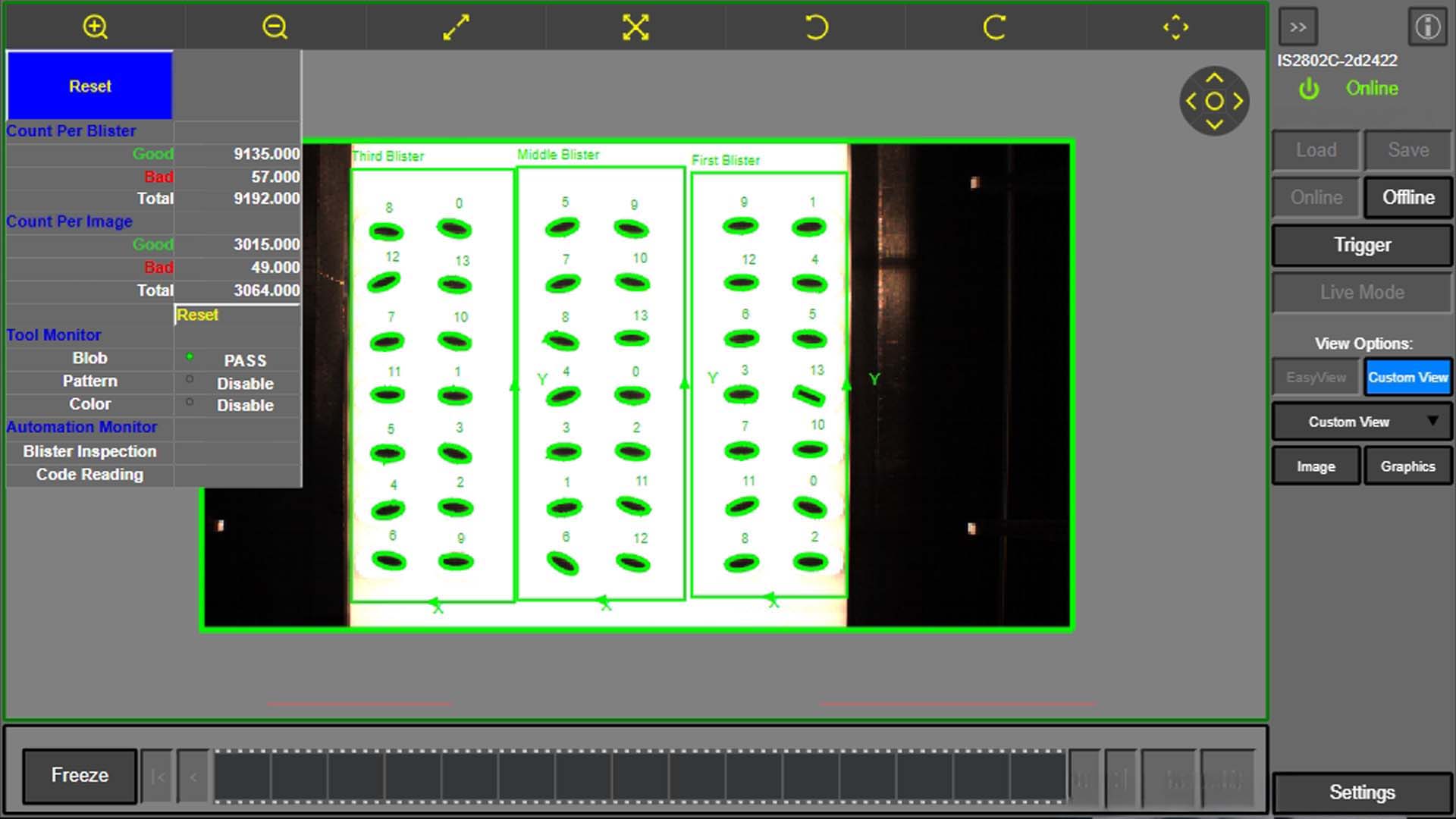

Visual Inspection of Blister Packs in Pharmaceutical Production

The pharmaceutical industry is exceptionally demanding, with every parameter requiring strict control and no margin for error. Yet, in many pharmaceutical production lines, outdated equipment still lacks modern inspection capabilities. As a result, quality control is often performed visually, leading to potential errors, delays, and increased costs due to rework or rejected products.

Technical Challenge and Solution

The pharmaceutical company that approached us was facing precisely this challenge: a lack of reliable quality control for blister packs. Their goal was to ensure that every pack leaving the production line was complete, accurate, and fully compliant with industry standards.

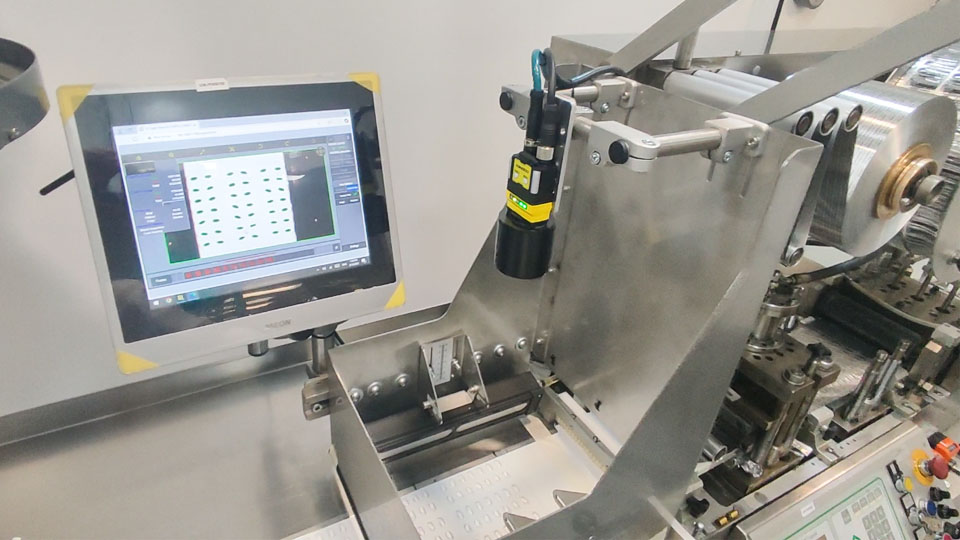

In response, we developed a visual inspection system that was integrated directly into the production machine and the rejection unit, transforming the existing line into a fully automated inspection environment.

The system:

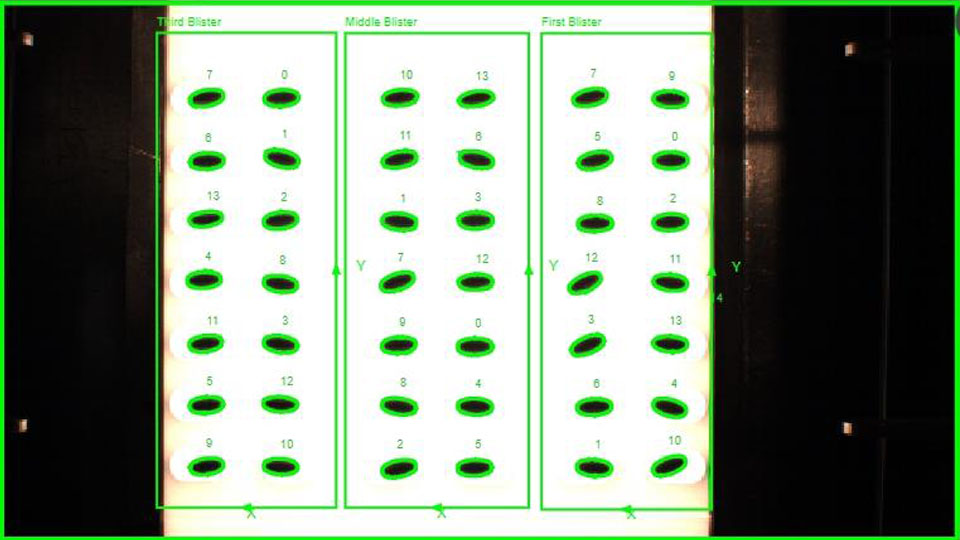

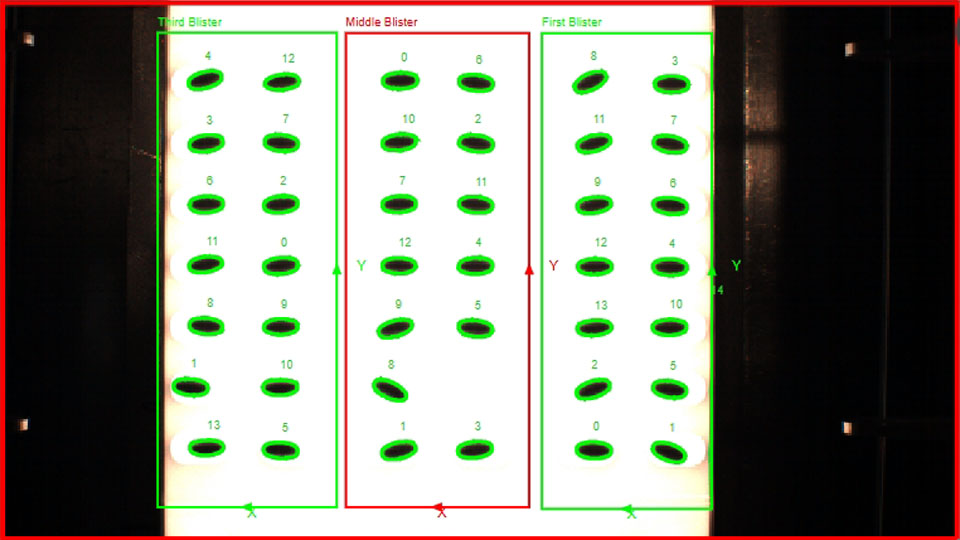

- Detects missing or mis-filled pills in each blister

- Detects missing pills

- Checks the color of the pills where necessary (Color Mix-Up)

- Adjusts the lighting according to the blister material (PVC or aluminum) for optimal clarity

At the same time, the system checks the exact location of each error to ensure that the machine's reaction concerns the correct piece.

All this is done in real time, without interrupting production. The system does not require special technical knowledge and is immediately manageable by the existing line operator.

Application Αdvantages

From the first moment of operation, the system proved its value, offering immediate benefits and justifying the investment choice. Specifically, the following were achieved:

- Zeroing out defective blister shipments

- Minimizing manual checks

- Strengthening traceability through images and data

- Fast return on investment, thanks to reduced inspection time and rejections

This investment gave new life to older equipment and transformed the line into a modern, efficient and completely reliable production unit without requiring structural changes or complex adjustments.

Upgrade your production line with optical inspection solutions that guarantee accuracy, speed, and full traceability.