Visual Inspection in Cigarette Packaging

In tobacco product packaging, every detail matters — from the alignment of the cigarettes to the precise application of the aluminum foil. Consistency in quality directly impacts the brand’s image and credibility. When a major player in the industry entrusted us with automating its quality control process, we designed and implemented a solution that met the demanding standards of this specialized sector.

Technical Challenge and Solution

For this project, we automated quality control at three critical points along the production line, aiming for zero tolerance in deviations, on a line operating at speeds of up to 500 packs and 10,000 cigarettes per minute.

The implemented system includes three consecutive visual inspection stations, integrated directly into the line:

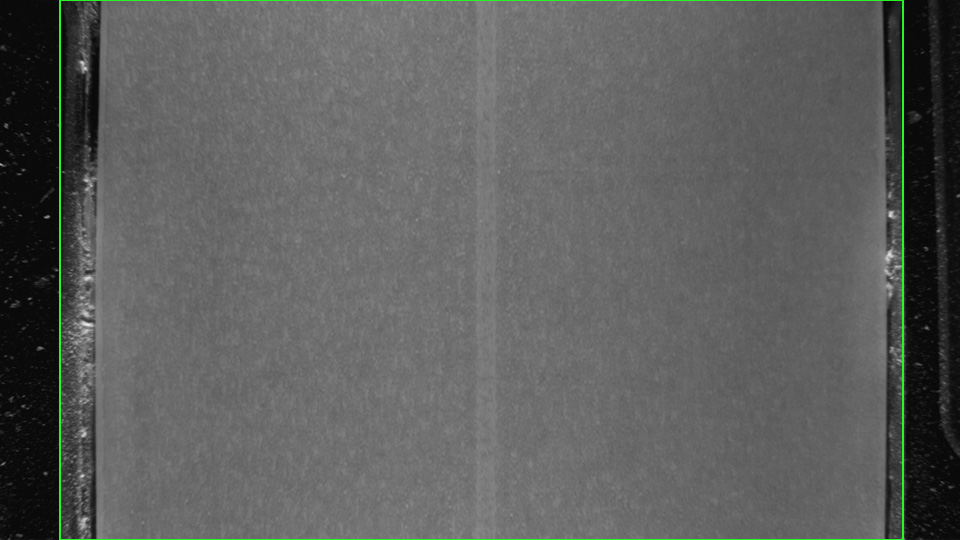

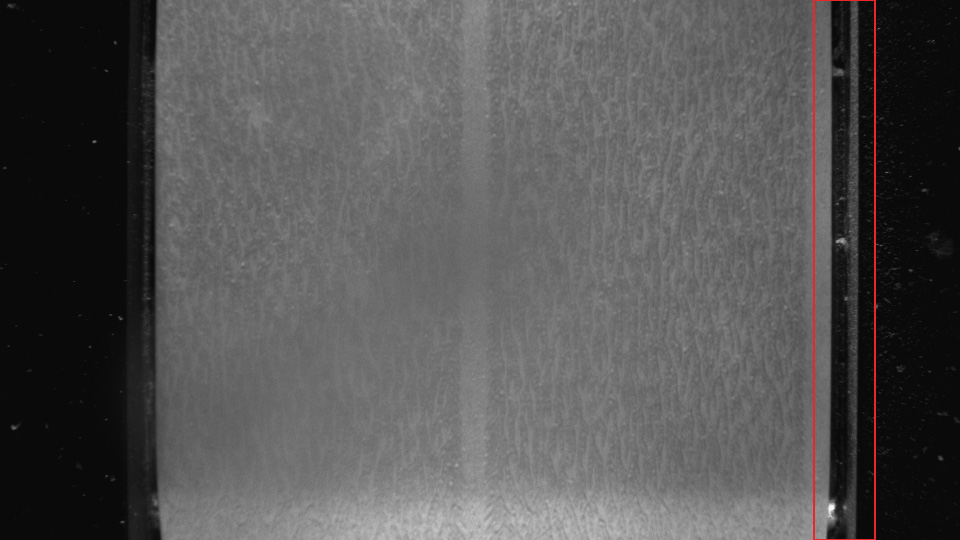

Checking the correct application of glue on the mouthpiece:

- Object: The cigarette holder paper (mouthpiece) before cutting

- Check: The presence of glue is confirmed in the correct places (left, center, right edge)

- Detection: Errors such as glue displacement or absence of glue

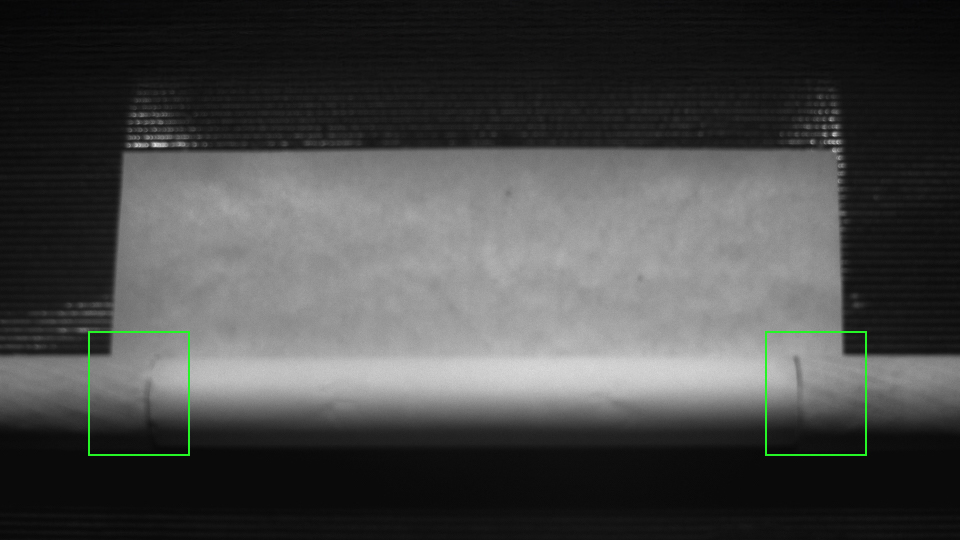

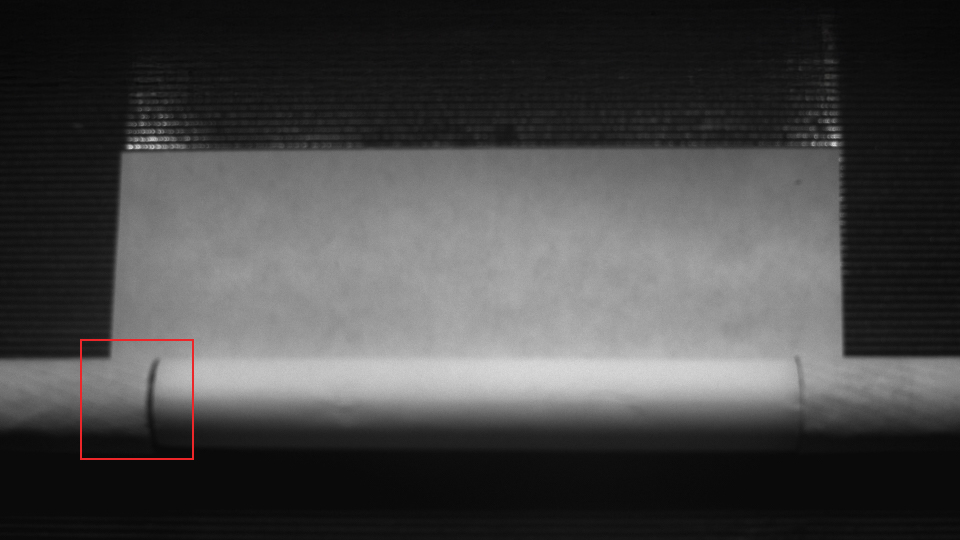

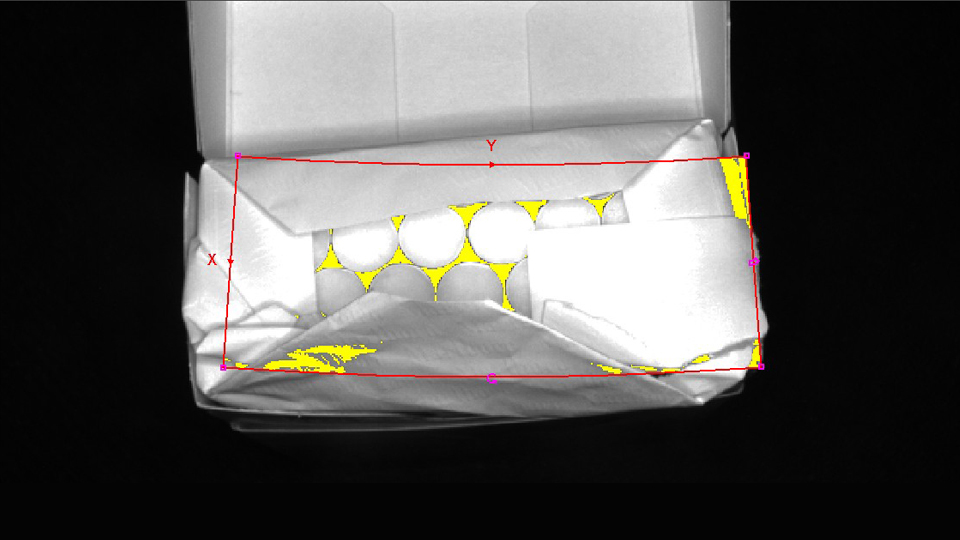

Checking the correct placement of cigarettes on the mouthpiece:

- Object: Placing two cigarettes on the mouthpiece

- Check: Alignment and exact position of the cigarettes with the gluing surface

- Detection: Out of position or non-contact cigarettes → error signal

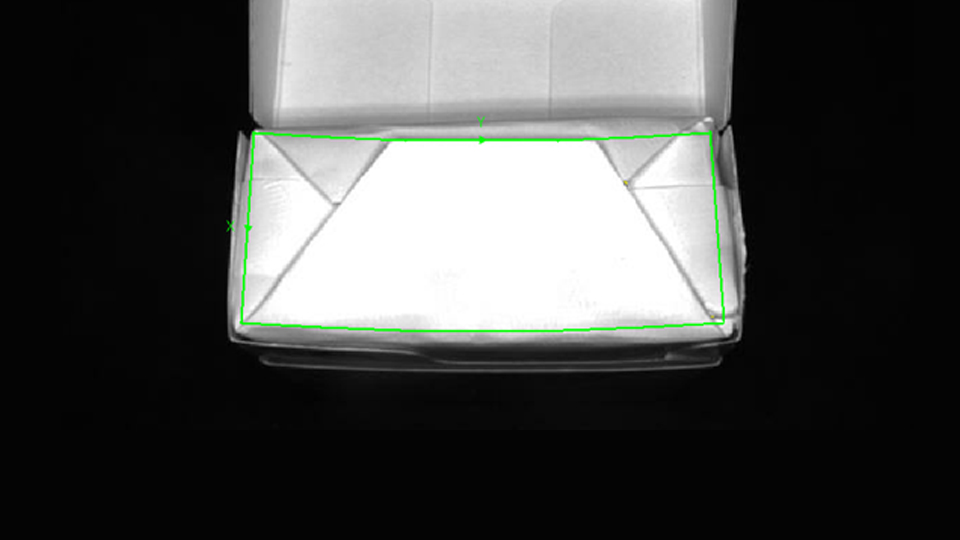

Checking the folding of aluminum foil:

- Object: Folding of aluminum foil inside the pack

- Check: It is confirmed that the aluminum foil covers the cigarettes correctly without any folding defects

- Detection: Visible content or incorrect folding → error signal

At all three stations, the cameras operate in real time and send output signals to the PLC to activate light/sound alerts or to stop and intervene in the line.

The implementation of this system was decisive, as such errors can cause:

- Poor appearance or incorrect functionality of the package

- Non-compliance with regulations for warnings

- Batch rejection, returns, or delays in the market

With the implemented solution, inspection became fully reliable and continuous, eliminating the need for manual checks or production slowdowns. The system was seamlessly integrated into the existing line, delivering substantial value without requiring major modifications.

Application Αdvantages

The system delivered results from day one, proving the value of the investment through clear, measurable benefits. Here are a few of them:

- Detect and reject defective packages and cigarettes before they reach the final stage

- Comply with the strictest industry standards

- Reduce rejects and rework costs

- Enable traceability of each batch through error logging

- Strengthen brand image and credibility through consistent quality

This project demonstrates how targeted application of machine vision technology can transform a traditional production line into a precision inspection system, impacting every stage of the process, from the factory floor to the store shelf.