Quality Control of Plastic Containers with Artificial Intelligence

In the plastics industry, ensuring the purity and integrity of the final product is a fundamental quality requirement, especially in food-related applications. Our collaboration with this company, a specialist in mold manufacturing and plastic food packaging, stemmed from its need for systematic and automated quality control to guarantee the highest standards in its production.

Technical Challenge and Solution

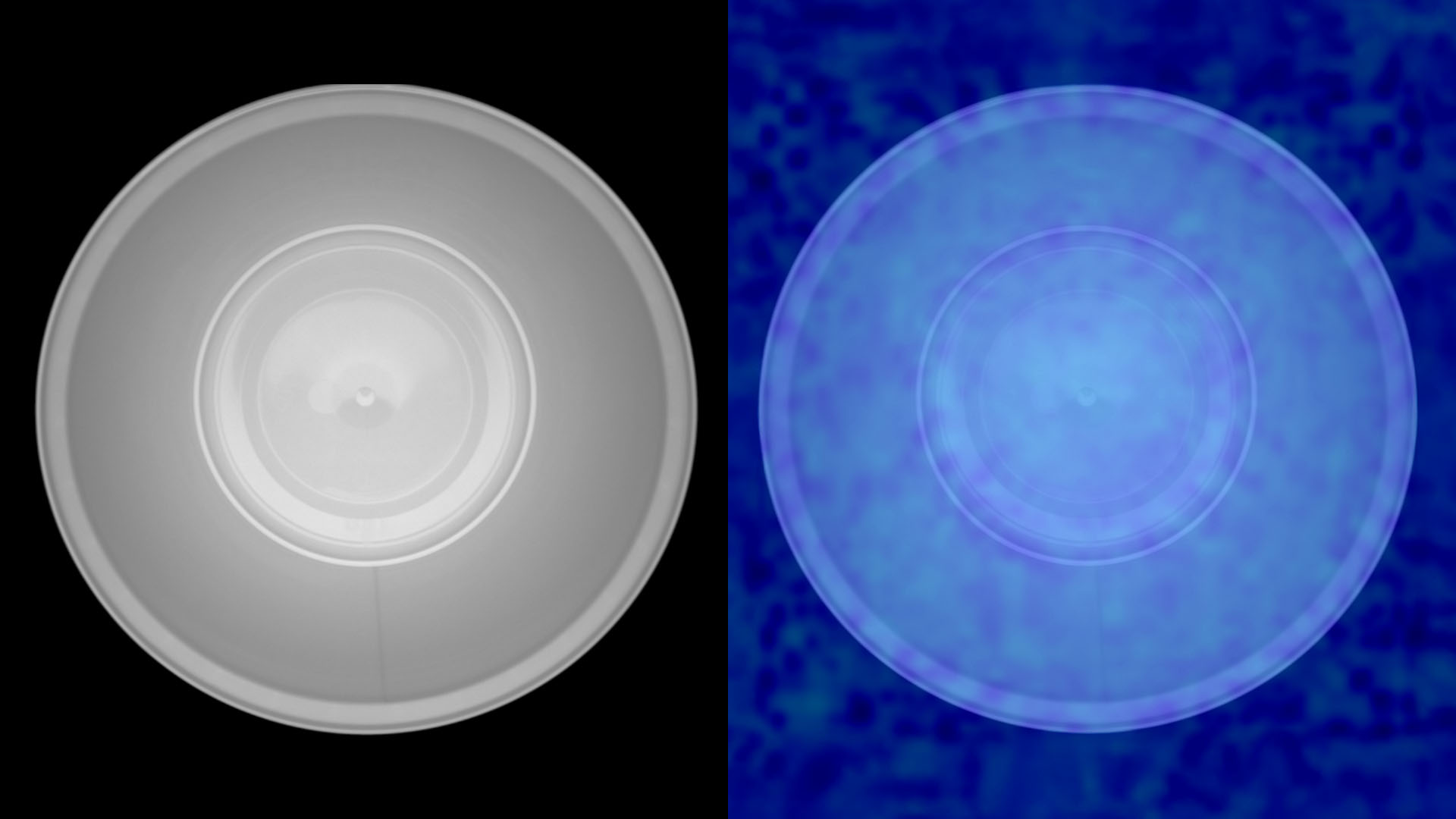

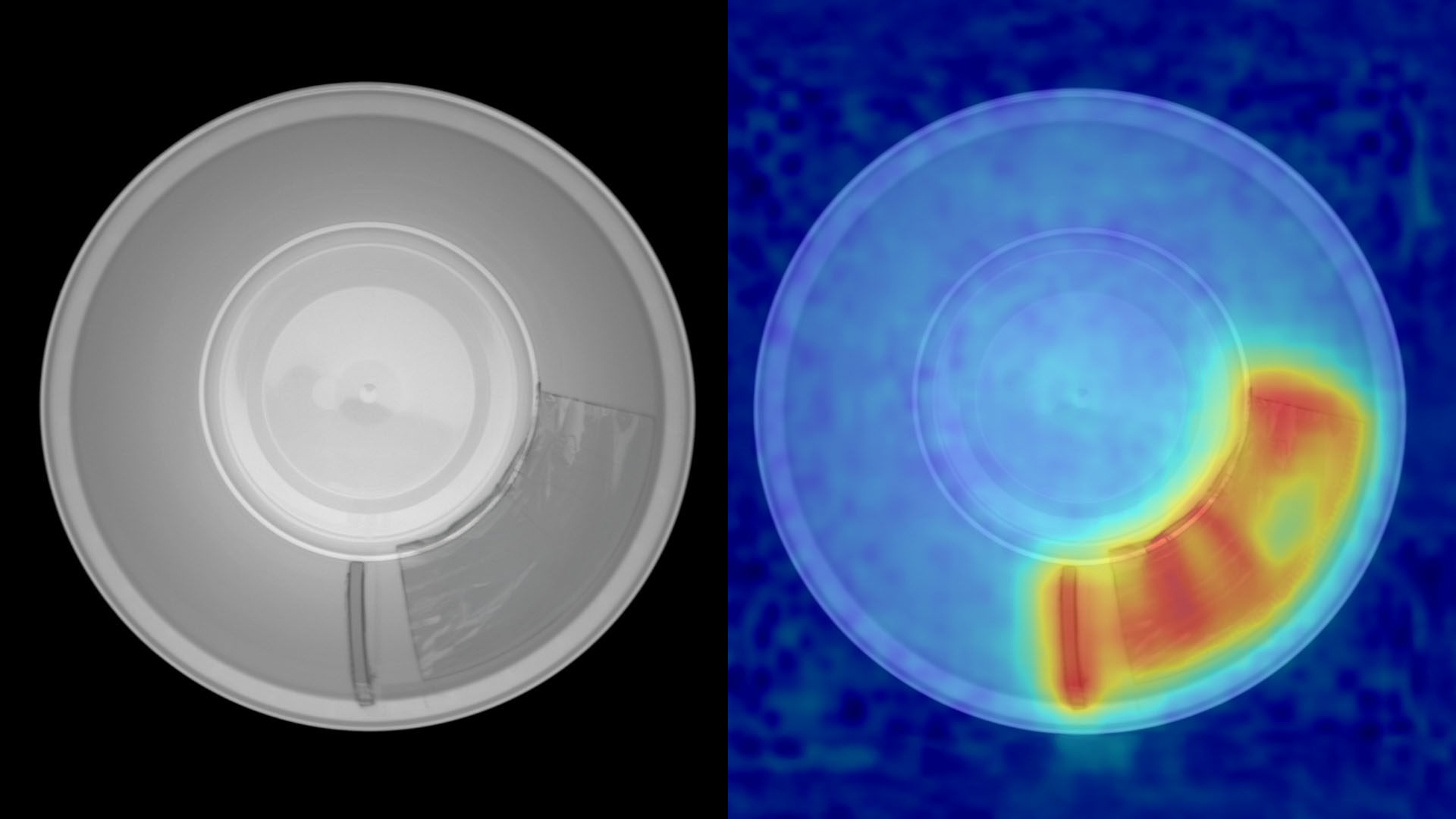

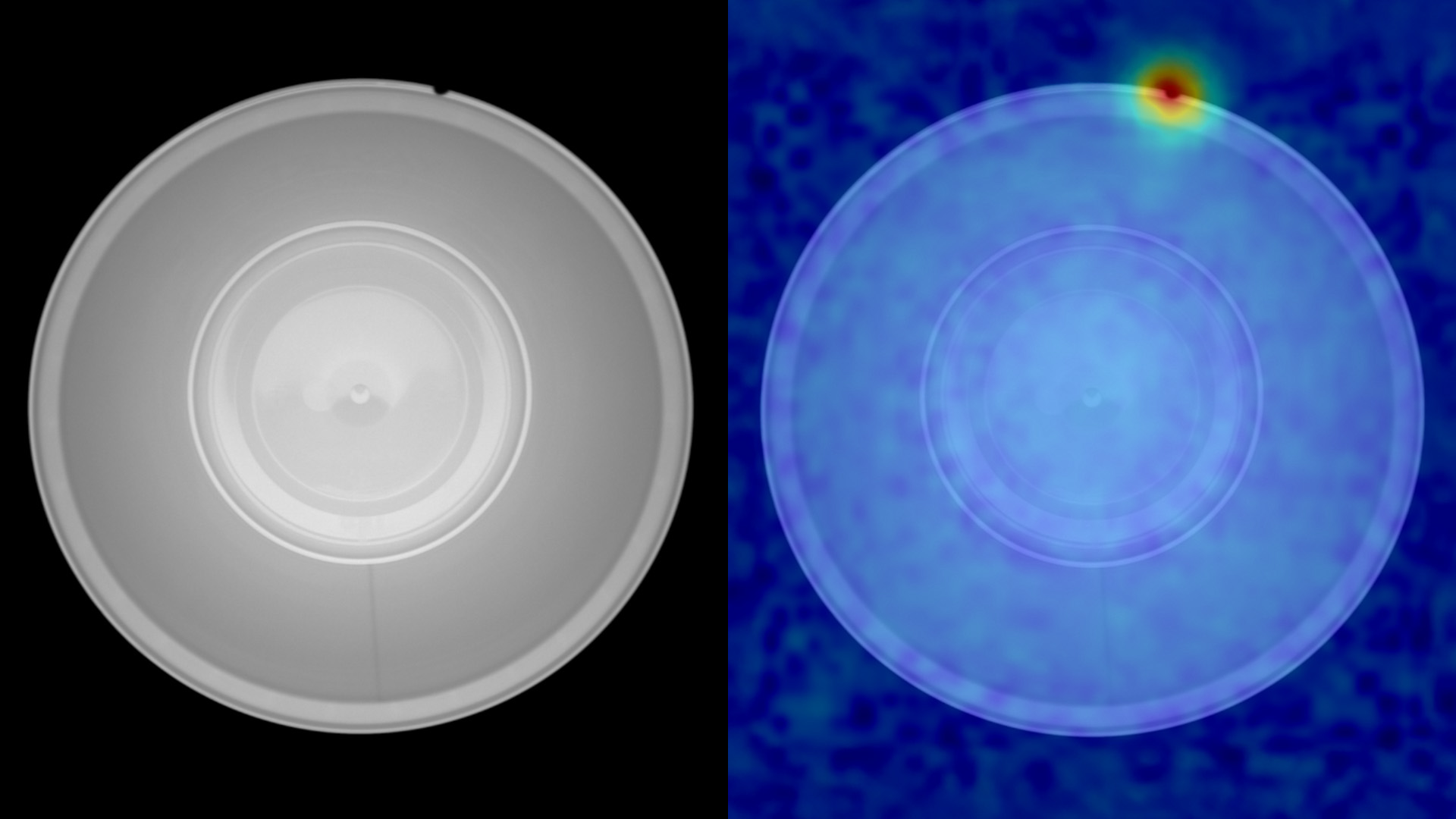

Specifically, the project involved the development and installation of a visual inspection system on a plastic container production line. The objective was to ensure fast and reliable inspection of both the interior and exterior of the containers, consistently detecting foreign objects, defects, and aesthetic flaws that might escape human inspection.

In this context, the goal was clear: to achieve 100% accuracy in controlling the orientation of each bottle, regardless of type or shape.

The solution we developed involves the use of three high-definition cameras:

- One for the bottom of the container

- One for the walls

- One for the external placement of the label

The cameras are connected to an industrial computer running artificial intelligence-based software. The system recognizes patterns and, having been trained on specific examples, provides real-time evaluation of the product as acceptable or not. It detects foreign objects,

spots, cracks, or incorrect labels. If a problem is detected, the piece is automatically transferred to a separate stack on the line, so that it can be picked up by operators.

Specifically, the process includes:

- Automatic image capture and processing

- Evaluation using AI trained on samples

- Activation of a beacon to inform operators

- Ability to store production statistics (Storage of accepted or rejected samples - Fail)

All this is done within a friendly and particularly simple-to-use work environment, which does not require special skills or technical training from its respective operator.

Application Αdvantages

The solution we designed and implemented delivers multiple benefits and, more specifically, ensures that:

- No defective container reaches the final packaging phase

- Errors and delays are reduced

- Production consistency and reliability are increased

- The need for subjective, manual checks is eliminated

The return on investment is achieved within a short period, thanks to reduced operating costs and increased inspection accuracy. In this case, the integration of a modern machine vision system added significant value and breathed new life into the existing production line, ensuring consistent product quality and strengthening the company's reputation and credibility.