Machine Vision in Machine Building

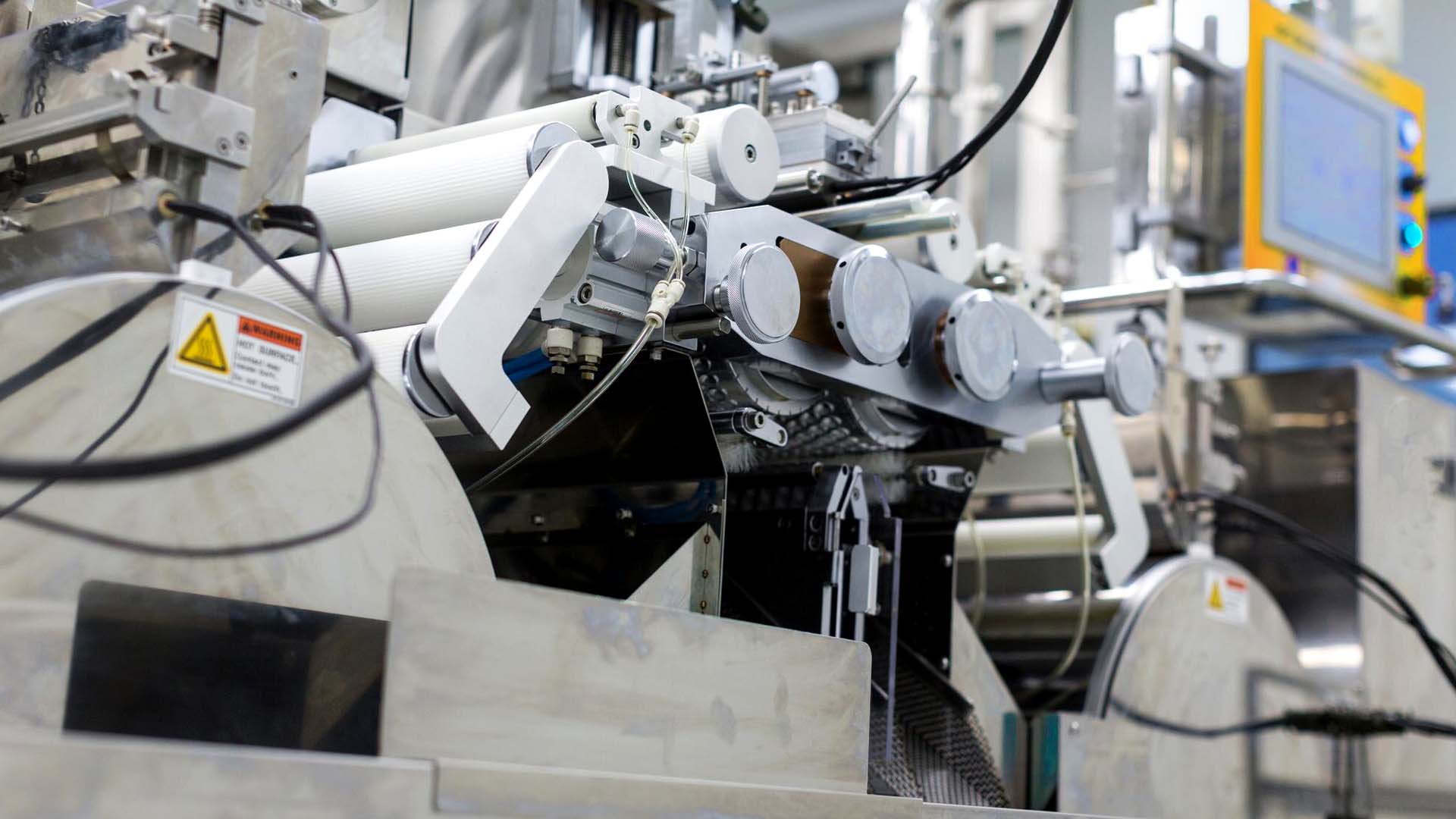

Machine builders require precision, efficiency, and adaptability to develop high-performance industrial machinery. Machine vision systems play a crucial role in automating inspection, assembly verification, and process optimization, ensuring that machines operate at peak performance.

Applications of Machine Vision in Machine Building:

Component Inspection: Ensures parts meet design tolerances by detecting defects, verifying dimensions, and identifying material inconsistencies before assembly.

Assembly Verification: Confirms the correct placement and orientation of components to prevent mechanical failures.

Weld and Joint Inspection: Analyzes welding seams and mechanical joints for integrity, reducing structural weaknesses.

Motion and Alignment Control: Assists in robotic positioning, precise part alignment, and tool calibration for high-precision machinery.

Marking and Traceability: Reads and verifies serial numbers, barcodes, and QR codes to maintain accurate production records.

Upgrading smart manufacturing

Integrate Robovision’s machine vision systems for precise quality inspections, production efficiency, and accuracy in complex manufacturing processes!