Machine Vision in the Tobacco Industry

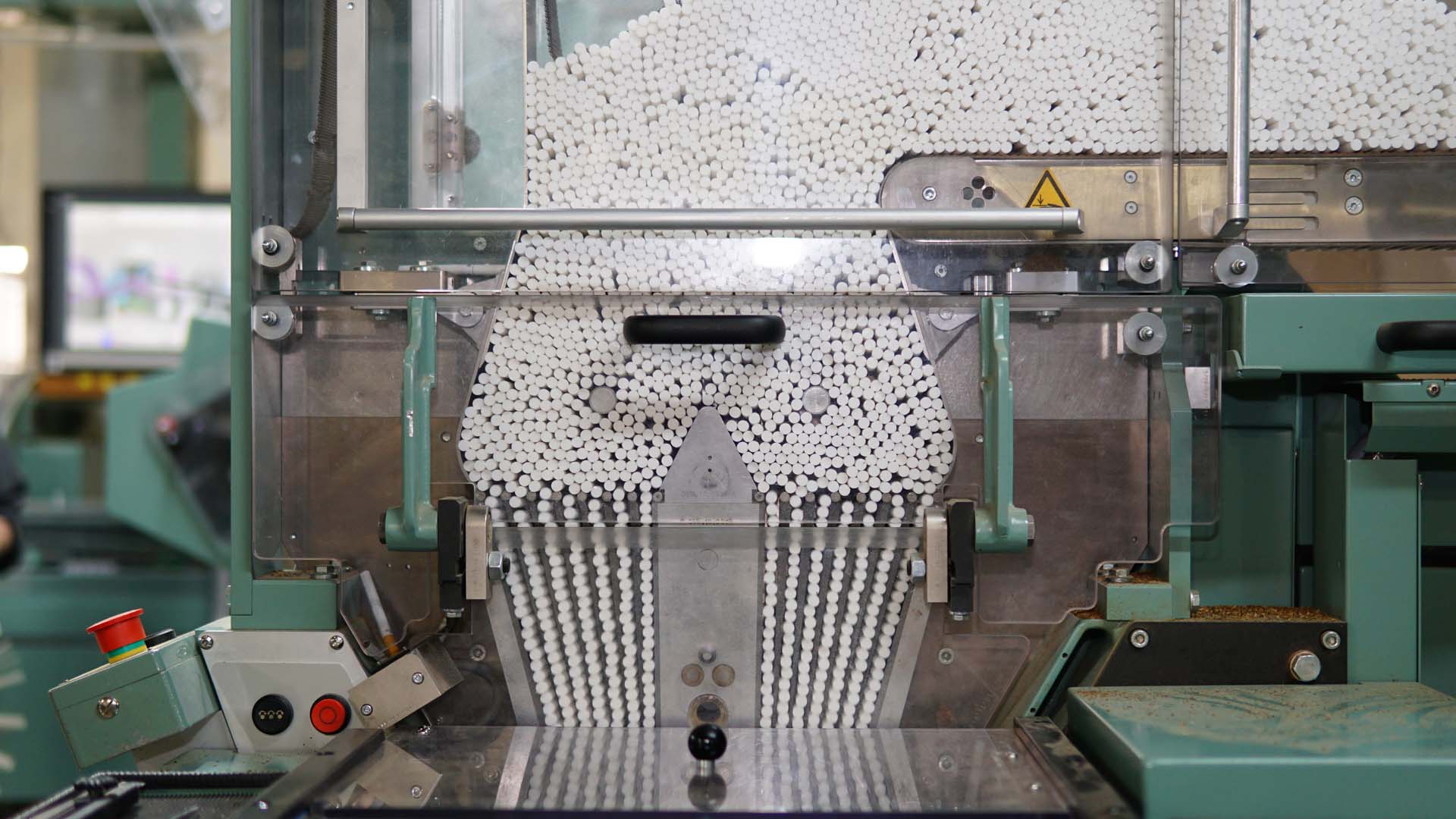

The tobacco industry demands precision and efficiency to meet high production volumes while maintaining stringent quality and regulatory standards. Machine vision systems automate inspection processes, ensuring consistency, compliance, and operational reliability throughout the production chain.

Applications of Machine Vision in the Tobacco Industry:

Leaf Quality Grading: Analyzes tobacco leaves for color, texture, and size to ensure only high-quality raw materials are used.

Cut Tobacco Sorting: Sorts cut tobacco by size and quality, removing non-compliant materials to improve uniformity and reduce waste.

Contaminant Detection: Identifies and eliminates foreign materials or contaminants during processing to maintain product purity and safety.

Fill Consistency Checking: Verifies the density and distribution of tobacco within cigarettes, ensuring uniform fill levels across all batches.

Filter Placement Inspection: Checks the placement and integrity of cigarette filters to meet design specifications and functional standards.

Packet Identification: Reads and verifies the packet’s unique serial number, usually in the form of a two-dimensional code, for tracing purposes.

Packaging Verification: Inspects packaging for structural integrity, correct labeling, and compliance with regulatory requirements, including health warnings and tax stamps.

End-of-Line Inspection: Conducts final checks on finished products for correct sealing, product counts, and overall quality before shipment.

Leaf Quality Grading: Analyzes tobacco leaves for color, texture, and size to ensure only high-quality raw materials are used.

Cut Tobacco Sorting: Sorts cut tobacco by size and quality, removing non-compliant materials to improve uniformity and reduce waste.

Contaminant Detection: Identifies and eliminates foreign materials or contaminants during processing to maintain product purity and safety.

Fill Consistency Checking: Verifies the density and distribution of tobacco within cigarettes, ensuring uniform fill levels across all batches.

Filter Placement Inspection: Checks the placement and integrity of cigarette filters to meet design specifications and functional standards.

Packet Identification: Reads and verifies the packet’s unique serial number, usually in the form of a two-dimensional code, for tracing purposes.

Packaging Verification: Inspects packaging for structural integrity, correct labeling, and compliance with regulatory requirements, including health warnings and tax stamps.

End-of-Line Inspection: Conducts final checks on finished products for correct sealing, product counts, and overall quality before shipment.

Fostering tobacco manufacturing

Optimize tobacco production processes, protect your brand identity, enhance consumer safety, and ensure compliance with stringent regulations through Robovision’s machine vision systems!