Machine Vision Systems with Deep Learning for Defect Detection and Smart Automation

Traditional industrial inspection methods rely on rigid rules and often fail to handle variations in production. This can lead to undetected defects, increased scrap, and limited flexibility.

Deep Learning is transforming industrial quality control by leveraging advanced algorithms to analyze visual data and address complex challenges.

At Robovision, we integrate Deep Learning processes into vision systems to enhance their ability to analyze, interpret, and act on visual information. By using large datasets of labeled images, our models learn to detect patterns, identify anomalies, and make precise decisions.

Key Features & Benefits

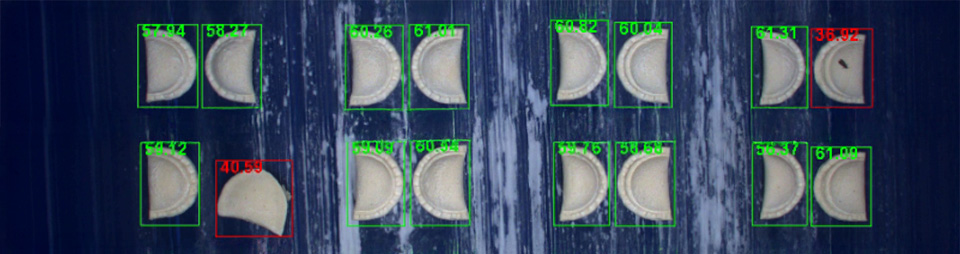

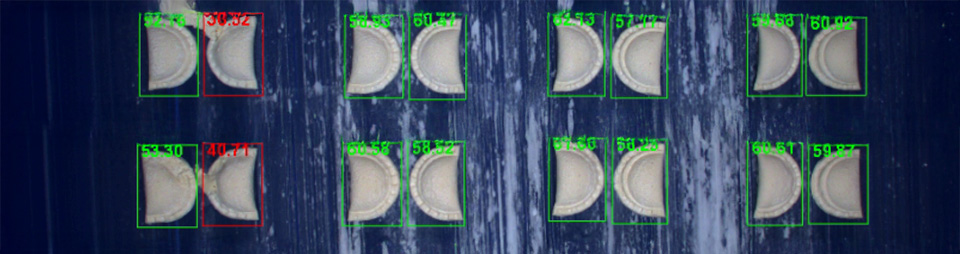

Defect Detection: Identifies subtle and complex defects that traditional methods cannot detect, ensuring high quality.

Classification: Sorts products into categories based on shape, size, or other criteria, streamlining production processes.

Object Detection: Pinpoints specific items or features within images, enabling accurate actions such as robotic pick-and-place.

Visual Quality Control: Evaluates features like texture and color to ensure products meet appearance standards.

Accuracy: Handles complex inspections with high precision, reducing errors and improving product quality.

Efficiency: Automates repetitive tasks, reducing manual effort and boosting productivity.

Scalability: Supports a wide range of applications, from small-scale operations to high-speed production lines.

Tackle even the most complex challenges with Deep Learning–based machine vision solutions, tailored to your production line’s requirements.