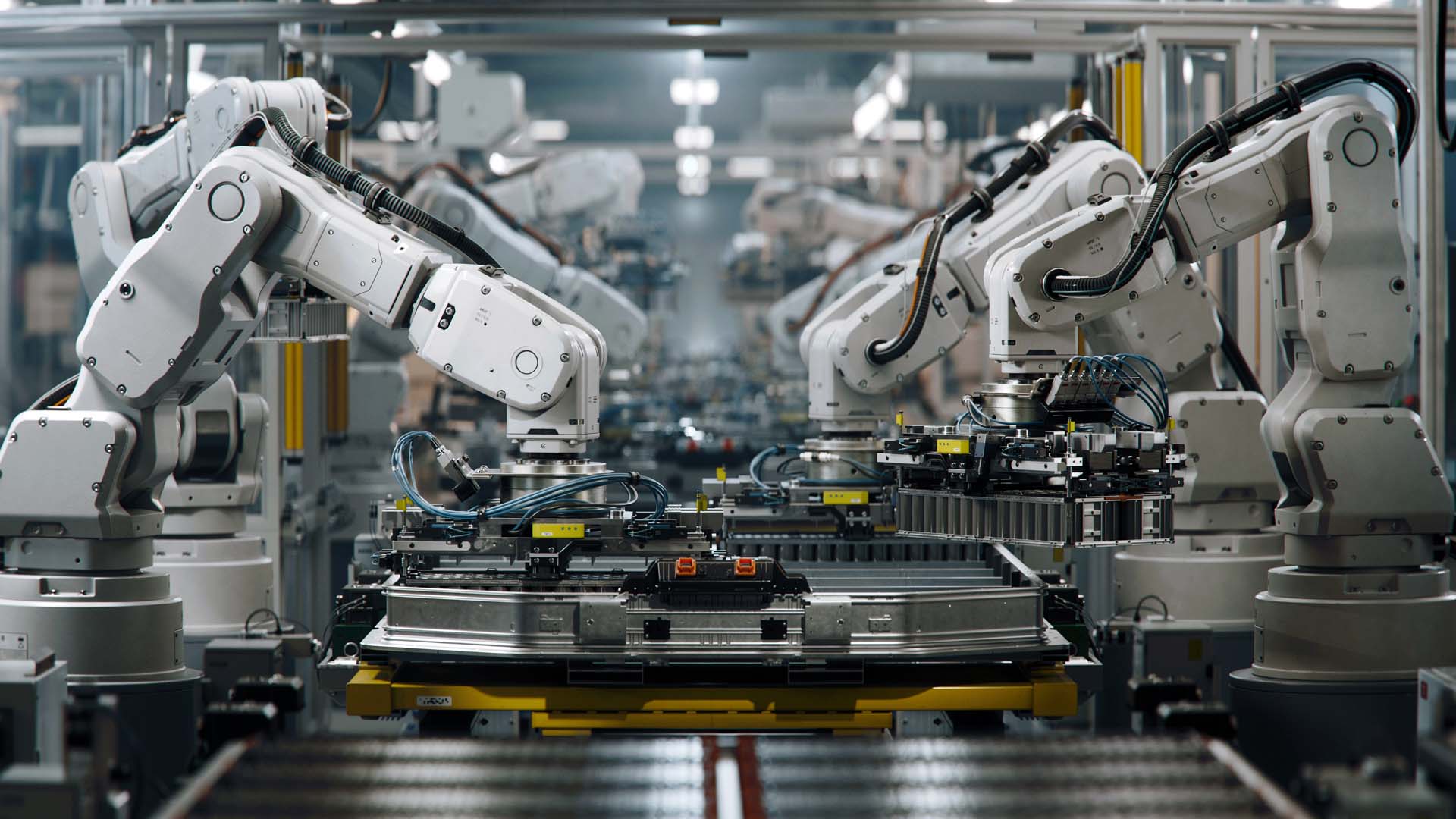

Robotics with Machine Vision for Automation and Precision

In many industrial processes, robots are limited to pre-programmed movements and cannot adapt to variations in size, shape, or object position. This results in reduced flexibility, frequent manual interventions, and higher operating costs.

Machine vision acts as the “eyes” of robotics, enabling robots to interpret and interact with their environment. By processing visual data, robots gain spatial awareness, adaptability, and precision—allowing them to perform even the most complex tasks with consistent quality.

Key Features & Benefits

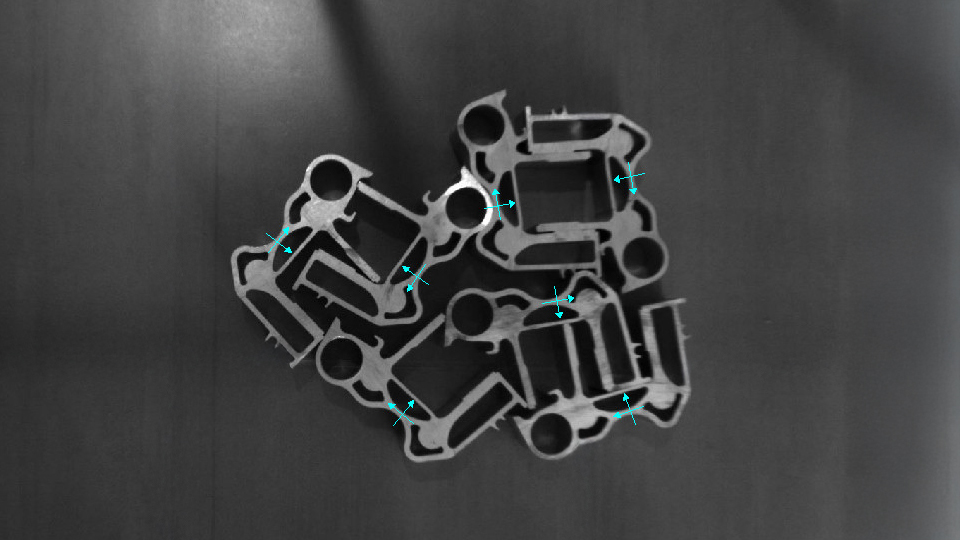

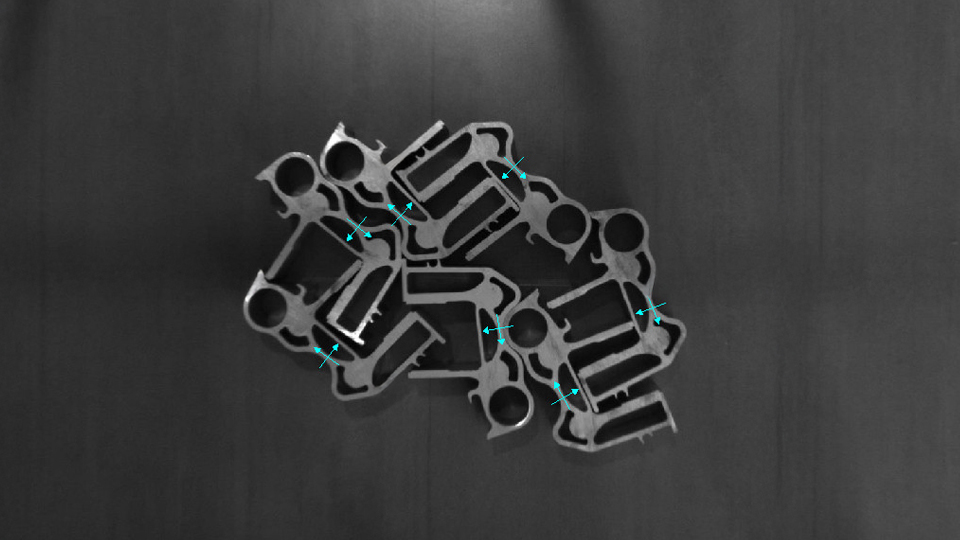

Object Recognition & Identification: Enables robots to detect and interpret object shapes and positions, supporting tasks such as sorting, picking, and placement.

Advanced Handling & Adaptability: With AI and machine learning, robots dynamically adjust to changes in size, shape, and orientation for reliable product handling.

Inventory Management: Vision-enabled robots count products, verify quantities, and monitor stock in real time, reducing human error.

Spatial Awareness for Precision Tasks: Depth perception and 3D data support complex operations such as assembly, welding, and material handling with micrometer-level accuracy.

Applications Across Industries

Bin Picking: 3D vision allows robots to detect and pick randomly placed objects from bins, optimizing efficiency in complex environments.

Quality Control: Ensures products are inspected for defects, maintaining consistent quality standards.

Sorting & Packaging: Vision-guided robots automate sorting and packaging processes, adapting to product line changes.

Integrate vision-guided robotics for precise handling, reduced reliance on manual processes, and consistent productivity, even in dynamic production environments.