Automated Surface Inspection for Defect Detection and Scrap Reduction

Hidden defects, micro-cracks, or texture inconsistencies can lead to high scrap rates, material waste, and increased production costs. With advanced machine vision technology, surface inspection systems detect flaws early and ensure that every product meets the highest quality standards.

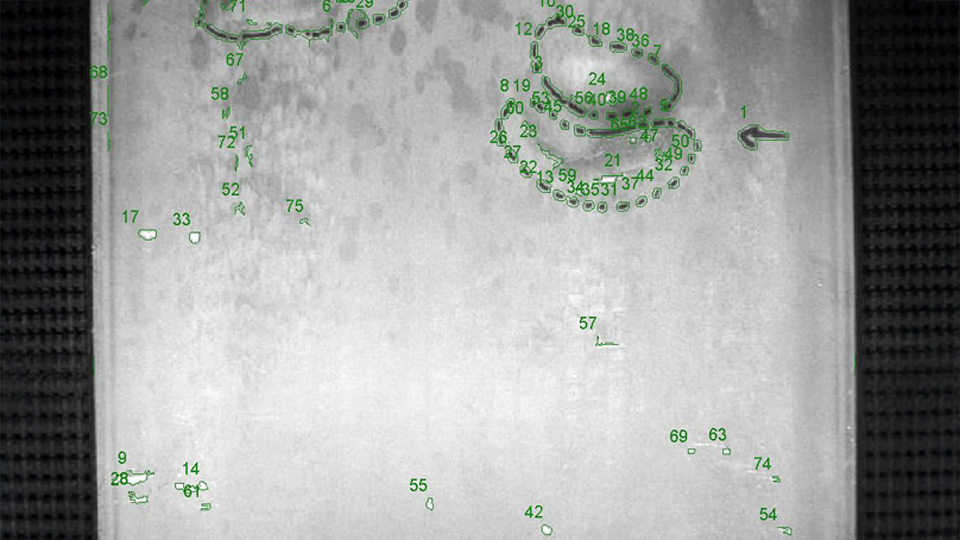

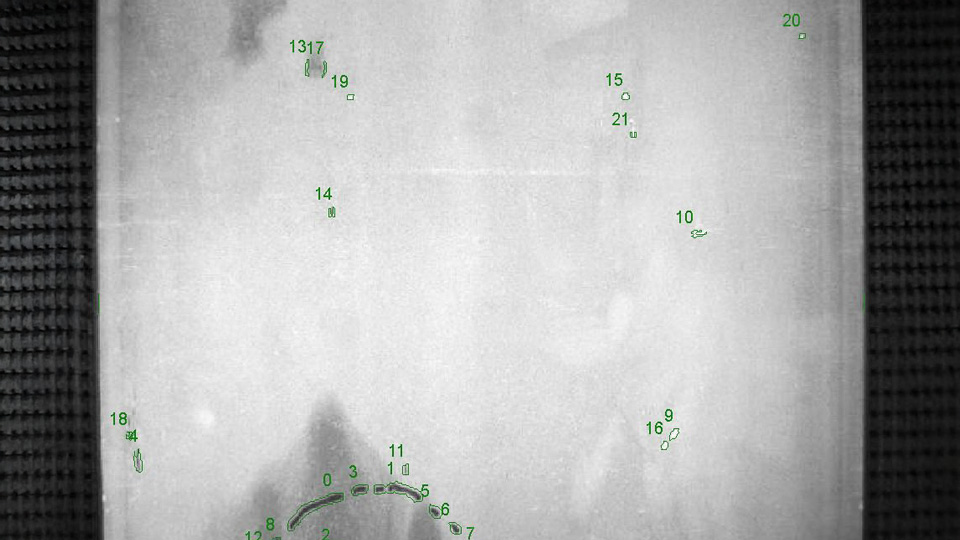

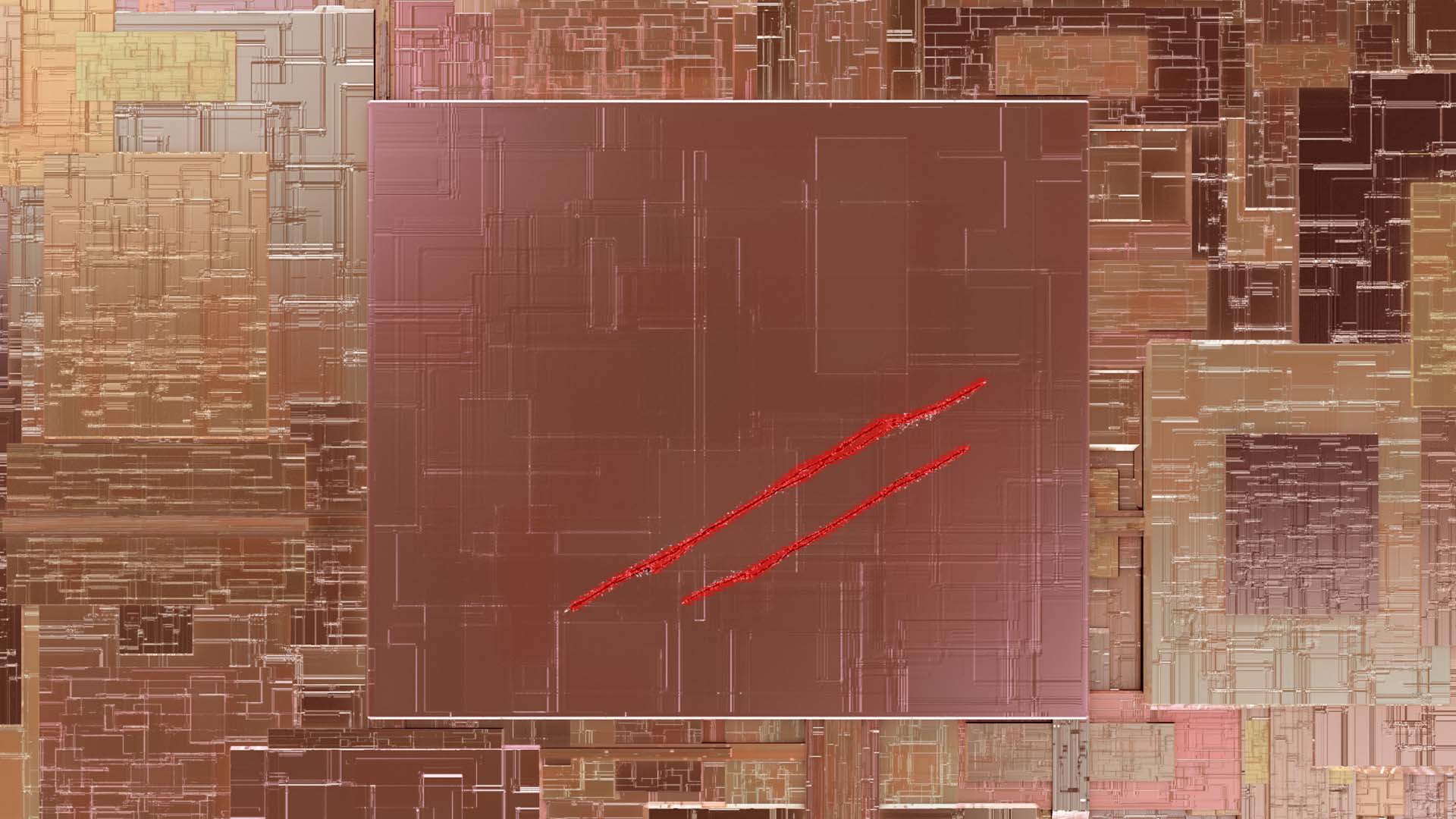

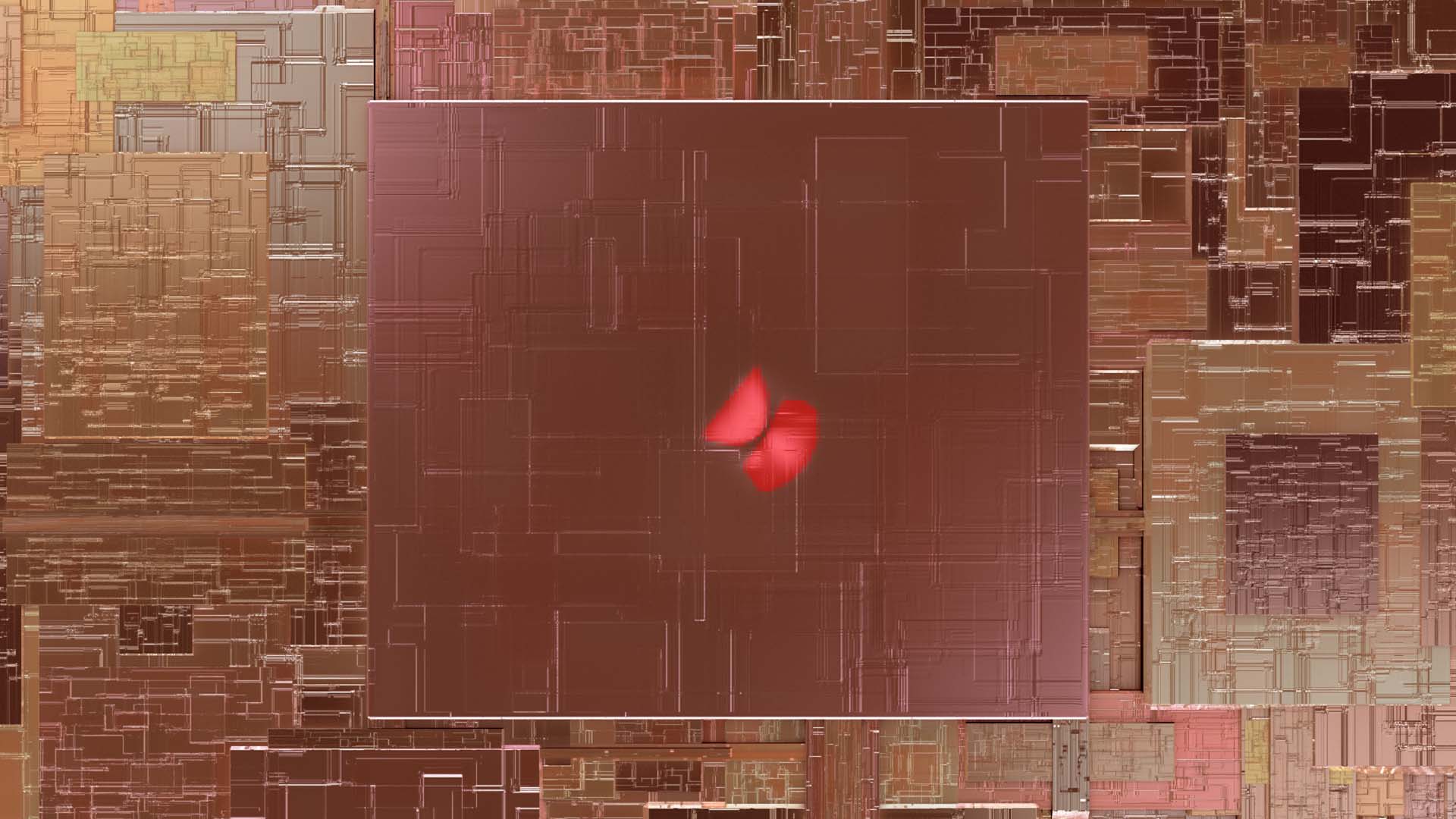

Using high-resolution cameras, sensors, and specialized lighting, surfaces are captured in detail and analyzed by AI algorithms to identify and classify defects such as cracks, dents, bumps, roughness, pinholes, and gaps.

Key Features & Benefits

Defect Detection: Accurately identifies surface flaws, ensuring compliance with quality standards.

Dynamic Operation: Inspects both static and moving objects at high speeds, adaptable to diverse production environments.

Material Flexibility: Works seamlessly on metals, plastics, wood, and composite surfaces.

Multi-Sensor Integration: Combines data from multiple sensors for full 360° inspection.

High Precision: Detects even the smallest anomalies at high production speeds.

Custom AI Algorithms: Advanced models reduce false positives by recognizing unique defect patterns.

Tailored Integration: Systems designed to fit the specific requirements of each production line.

Applications Across Industries

Automotive: Inspects paint, welds, and scratches on parts and bodies.

Metallurgy: Detects cracks and inconsistencies on metal sheets and components.

Electronics: Ensures housing and display quality through detailed inspection.

Packaging: Verifies integrity and cleanliness of packaging in real time.

Woodworking: Identifies cracks and texture flaws in wooden panels and products.

Food & Beverage: Inspects product and packaging quality, detecting contaminants or surface defects.

Robotics: Recognizes items on pallets and conveyors, supporting pick-and-place applications.

Ensure consistent product quality by meeting strict quality standards and strengthening your reliability in the market.